Artificial Intelligence-enabled escalator combs enhance passenger safety

Escalators provide a convenient way to move between floors within buildings, as well as to access public transport and pedestrian flyovers. But they are vulnerable to damage caused by small objects, such as screws and coins, getting caught in the gaps between the escalator combs and the step treads at the top and bottom of escalators. Such incidents can lead to escalators being damaged. More seriously, the sudden halts that may occur when an object becomes jammed in the escalator comb, can lead to injuries among passengers using the escalator. As a result, reducing the occurrence of these incidents plays an important role in enhancing escalator safety.

Reimagining escalator combs

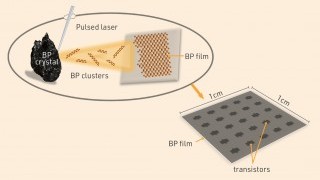

To help overcome this issue, PolyU undertook a consultancy project for the Electrical and Mechanical Services Department (EMSD) of the HKSAR Government to redesign and re-engineer the combs used in escalators. Ir Dr Curtis Ng from PolyU’s Department of Mechanical Engineering collaborated with Mr William Au, Senior Engineer/General Legislation of EMSD, Avaron Technologies Limited and Anlev Elex Elevator Limited, to develop the Artificial Intelligent Nylon Optical Fibre Sensing Escalator Combs, replacing the traditional metal combs.

The team used 3D scanning and multi jet fusion 3D printing technology to create escalator comb plates made out of a new nylon material with greater flexibility. The nylon combs not only have good ductility and resilience, but they can also bounce away foreign objects that fall on to them. In fact, in a pilot test, the nylon combs successfully bounced away all eight screws from an escalator step on to the platform.

Another issue with the traditional metal escalator combs is that the teeth can be easily broken or popped out of place when a hard foreign object becomes lodged in them, creating a risk for passengers. By contrast, the higher flexibility of the nylon combs has greatly reduced the possibility of such damage. The coverage of the new nylon combs was also extended by five millimetres to reduce the gap between the comb and the escalator steps, further reducing the chance of foreign objects getting stuck there.

Ir Dr Curtis Ng of PolyU collaborates with EMSD and industry partners to develop a new type of sensing escalator comb (left) that can bounce away foreign objects (middle) and enable real-time escalator monitoring (right).

Harnessing AI to detect objects

The team’s innovations did not end there, and optical fibre sensing and artificial intelligence (AI) cloud analysis technologies were also applied to the nylon combs to enable the escalators to be monitored in real-time. Through monitoring the vibrations of the combs, the device is able to detect the presence of foreign objects. If a foreign object is detected, a mobile phone alert is sent to the management company responsible for the escalator, so that the object can be removed before it damages the escalator or causes it to stop.

The sensing combs can also be used to monitor wear and tear on individual escalator parts, facilitating preventative maintenance, minimising the possibility of accidents, and reducing the time escalators may be out of use for emergency repairs. In addition, the monitoring system can be used to analyse pedestrian flow.

The system has been tested on eight escalators, including ones located in outdoor covered walkways, a government complex and large shopping malls. The real-time detection technology greatly reduced the occurrence of escalator incidents. EMSD plans to promote the system for use by the Airport Authority and MTR Corporation, while the Vocational Training Council is planning to use the device for teaching purposes.

Low-cost customisation

A further benefit of using multi jet fusion 3D printing technology to manufacture the nylon escalator combs is that they can be customised at a negligible cost to meet individual requirements. Examples of how the combs can be customised include giving them reduced clearance, producing them in different colours or having different safety messages written on them.

Award winning innovation

(From right) Mr Tsang Tsz-fung (EMSD), Ir Dr Curtis Ng (PolyU), Mr William Au (Senior Engineer of EMSD), Dr Cheng Kei-chun (Avaron Technologies Limited), and Mr Ng Yuk-kin (Anlev Elex Elevator Limited)

The invention won a Gold Medal at the Special Edition 2021 Inventions Geneva Evaluation Days – Virtual Event. The innovation demonstrates how PolyU, government and industry can collaborate and make good use of technology to create real-world solutions that help enhance people’s everyday lives.