Highly permeable, superelastic conductor shapes future wearable electronics

Other Articles

Researchers at PolyU have developed a new type of stretchable conductor that is highly permeable and superelastic with good conductivity. The new conductor serves as a platform enabling the making of monolithic stretchable electronics that integrate many components in a small area, provide multiple functions and endure hours for wearing. Potential applications include health monitoring devices, soft robotics and on-skin electronics.

Wearable technology such as fitness trackers and smartwatches are everywhere nowadays. Smart glasses and biometric apparel are gaining momentum. Electronic skin and electronic eye are no longer sci-fi inventions. As the range of wearable technology products expands, industry insiders predict wearable gadgets is the next big market after smartphones.

Stretchable electronics are innovating rapidly. Devices with electronic circuits embedded in substrates are found as skin electonic patches and biomedical implants in the healthcare industry. Currently, stretchable electronics are manufactured with impermeable elastic thick films. This method rules out multi-layered designs and hinders the development of devices with advanced functionalities. Low-permeability devices may also irritate the skin and cause inflammation and other health issues when wearing the devices for a long time.

New type of conductor - superelastic and highly permeable

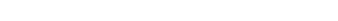

A PolyU research team, led by Professor Zheng Zijian of the Institute of Textiles and Clothing (ITC) with interdisciplinary academics from the Department of Applied Physics (AP) and the Department of Biomedical Engineering (BME), has recently made a breakthrough in a highly permeable and superelastic conductor. Their research “Permeable superelastic liquid-metal fibre mat enables biocompatible and monolithic stretchable electronics” was recently published in Nature Materials.

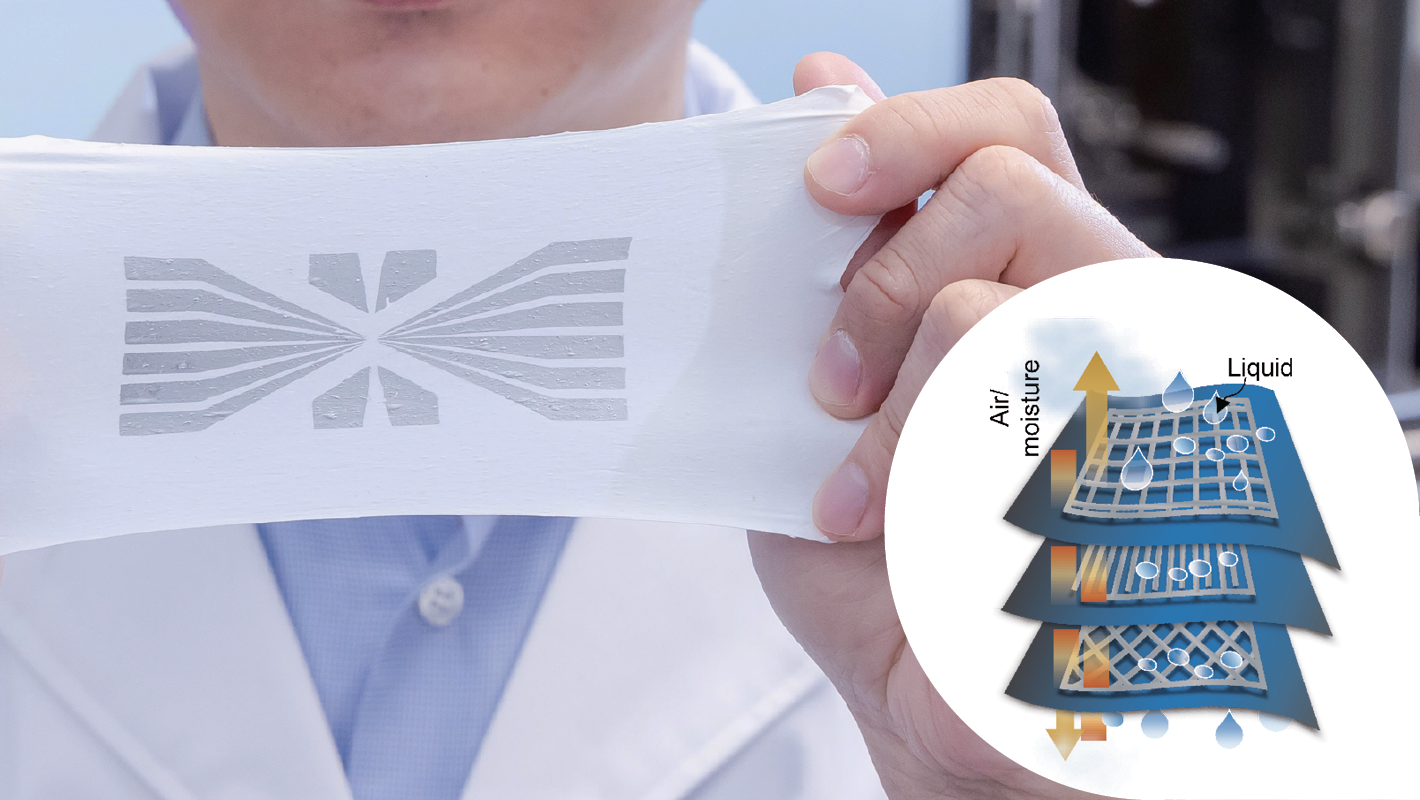

This novel conductor is called liquid-metal fibre mat (LMFM). The process of producing LMFM takes two major steps. First, liquid-metal is coated or printed onto a fibre mat during a special production method called electro-spinning. The fibre mat has the elastic properties of natural rubber. Second, the coated mat is stretched repeatedly until the liquid metal forms a porous buckled film hanging among the fibres.

Eutectic gallium-indium alloy (EGaIn) is selected to manufacture the LMFM as the conductive component for printing on a stretchable mat made of poly(styrene-block-butadiene-block-styrene), or SBS.

“EGaIn is a type of liquid metal commonly used in soft electronics, such as flexible printed circuit boards,” Professor Zheng said. “It can be maintained in a liquid state under room temperature and has low viscosity, high conductivity and low toxicity. When exposed to air, it forms a thin solid layer of oxide (Ga2O3) rapidly on the surface and becomes soft and stretchable. And SBS is a material usually used for rubber products, such as gloves or balloons.”

Therefore, the LMFM is super-stretchable and highly permeable. A sample made in the laboratory shows its moisture permeability is 22 times higher than a regular medical patch. It also retains stable conductivity in tensile testing. When further tested on rabbit skins, the LMFM showed excellent biocompatibility without irritation.

By coating or printing liquid metal onto an elastic electrospun fibre mat, the resulting LMFM becomes stretchable (left) and highly permeable (right) at the same time.

Multi-layered design to serve multiple functions

The research team also tested the effectiveness of a multi-layered LMFM. The researchers stacked three layers of printed EGaIn electrical circuits on monolithic elastic mats. Each layer acts respectively as an electrocardiography (ECG) sensor, a sweater sensor and an electrothermal heater. The three-layered sample, with a total thickness of merely 1 mm, performed all three functions effectively. The test indicated the stacked architecture of the LMFM suits to make multi-purpose wearables that can be worn for a long period.

The Hong Kong Scholars Program and the Research Grants Council of Hong Kong are the main funders of this project. The research team will continue to improve the performance of the LMFM, which shows great potential in health monitoring devices, soft robotics, on-skin electronics and prosthetics. The team strives to develop various healthcarerelated electronic devices and systems, and prioritises producing wearable electrocardiographic monitoring equipment.

Professor Zheng Zijian (front) and research team members (from left) Dr Huang Qiyao, Research Assistant Professor of ITC; Miss Zhuang Qiuna, PhD student; Dr Zhao Xin, Assistant Professor of BME; and Dr Chai Yang, Associate Professor of AP