Brief description of laboratory:

This laboratory “Laboratory for Adaptive Tubular Structures” under the auspices of The Chinese National Engineering Research Centre for Steel Construction (Hong Kong Branch) will integrate the use of testing methods and simulation-based engineering science for the understanding of the material characterisation, structural behaviour, and design of tubular composite structures under various loadings. It will also focus on the development of new connection technologies such as interlocking and demountability for reuse and sustainable construction environment.

Research Team of the of the Laboratory for Adaptive Tubular Structures:

Laboratory-in-charge:

Dr HU Yi-Fei

Member:

Dr SELVARAJ, Sivaganesh (Research assistant professor, PolyU)

Dr DEBNATH, Partha (Postdoctoral Fellow, PolyU)

Dr WANG, Chen (Postdoctoral Fellow, PolyU)

Dr CHEN, Shuxian (Postdoctoral Fellow, PolyU)

Dr GUO, Jiachen (Postdoctoral Fellow, PolyU)

Dr LIU, Haixin (Postdoctoral Fellow, PolyU)

Mr HAN, Xiaozhou (PhD candidate, PolyU)

Mr ZHAO, Shentao (PhD candidate, PolyU)

Collaborators:

Prof XU Fei (Professor, Chongqing University)

Dr ZHU Jiongyi (Lecturer, Shanghai University)

Dr CHEN Junbo (Lecturer, Huazhong University of Science and Technology)

Dr LIU Junzhi (Lecturer, Beijing Normal University)

Research Programmes/Themes:

Adaptive Tubular Structures

Tubular structures are synonymous with modern architecture, primarily in line with nature, like bamboos. The familiar range of tubular shapes sections includes square, rectangular, circular, elliptical, and polygonal tubular sections. Tubular structures can be found in many structural applications including buildings, bridges, wind turbines, off-shore platform. Due to the closed-form nature, concrete infill become a natural consequence to enhance strength and stiffness and a concrete-filled member which has an excellent load-bearing, ductility, and energy dissipation capacity.

Main projects:

Project 1. Material characterisation and constitutive model of cold-formed steels

Objectives:

(1) To propose predictive expressions for material properties of cold–formed steel.

(2) To establish the stress–strain relationship incorporating strength enhancement models of cold–formed steel.

Figure 1. Effects of fu,f/fy,f ratio and ri/t ratio on the strength enhancement behaviour.

Figure 2. Trend between the change of ultimate strain and related parameters.

Figure 3. Comparison of the stress–strain curves predicted from one–stage model based on measured or predicted material parameters with test stress–strain curves.

Conclusions:

An extensive database comprising more than 900 tensile test results was developed based on the obtained test results and collected data from the global literature. Predictive expressions for the key material parameters of cold-formed steels in the corner region have been derived based on the analysis of the developed database. According to the statistical results, the predicted material parameters are shown to be in great agreement with test results. A material constitutive model was then proposed to accurately describe the stress–strain response of cold-formed steel in the corner region, while the key parameters used in this model can be determined from the abovementioned predictive expressions.

Reference:

H. Liu, J. Chen, T.-M. Chan, Predictive models for material properties of cold-formed conventional steels in the corner region, Thin-Walled Structures 187 (2023) 110740.

Project 2. Behaviour and design of cold-formed polygonal hollow section columns

Objectives:

(1) To study and characterise the material properties and the residual stress distribution within the cold-formed polygonal hollow sections.

(2) To study the structural behaviour of cold-formed polygonal hollow section columns subjected to concentric compression.

(3) To propose suitable design guidelines concerning the cross-section classification limits, cross-section resistance, and member buckling strength for cold-formed polygonal hollow section columns.

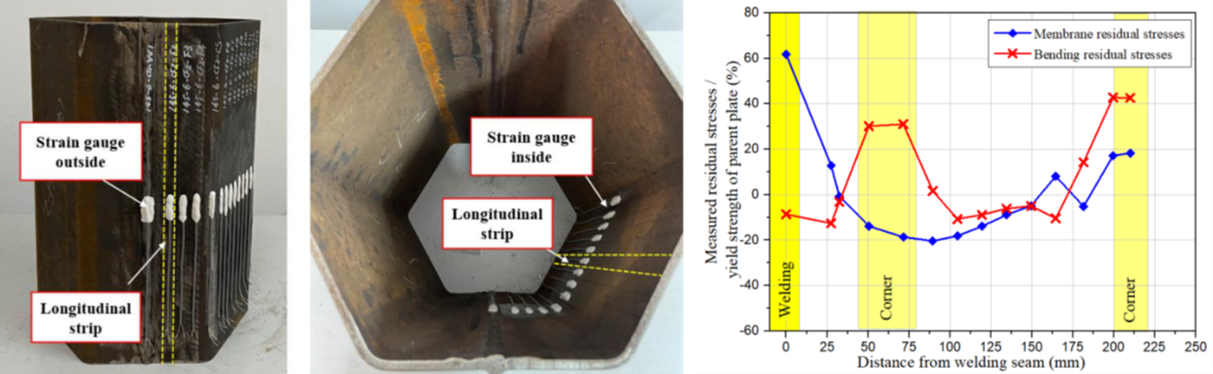

Figure 1. Residual stresses measurement and distribution.

Figure 2. Test setups for cold-formed polygonal hollow section columns.

Figure 3. Assessment of the design codes for the cross-section resistance and column buckling strength.

Conclusions:

The degree of the strength enhancement for corner portions due to press-braking was quantitatively and graphically analysed. Based on the observed consistent pattern of residual stress distributions in polygonal hollow sections, simplified residual stress predictive patterns was proposed. Design guidelines concerning the cross-section classification limits, cross-section resistance, and member buckling strength for cold-formed polygonal hollow section columns have been proposed.

References:

J. Chen, H. Liu, T.-M. Chan, Material properties and residual stresses of cold-formed octagonal hollow sections, Journal of Constructional Steel Research 170 (2020) 106078.

J.Z. Liu, H. Fang, T.M. Chan, Experimental investigations on material properties and stub column behaviour of high strength steel irregular hexagonal hollow sections, Journal of Constructional Steel Research 196 (2022) 107343.

J.Z. Liu, H. Fang, T.M. Chan, Numerical investigation on local buckling behaviour of cold-formed high strength steel irregular hexagonal hollow section stub columns, Thin-Walled Structures 185 (2023) 110571.

Project 3. Development and Behaviour of the Swift-Constructed Demountable Blind Bolt (SCDBB) for Structural Hollow Section Connection

Objectives:

(1) To develop a new type of demountable blind bolt which has satisfactory strength and mechanical performance, as well as can be installed and demounted more easily and faster;

(2) To improve the tensile stiffness of Hollo-bolt, and achieve better tensile strength than Reverse Mechanism Hollo-bolt;

(3) To derive the corresponding behaviours of the proposed blind bolt and put forward the design recommendations.

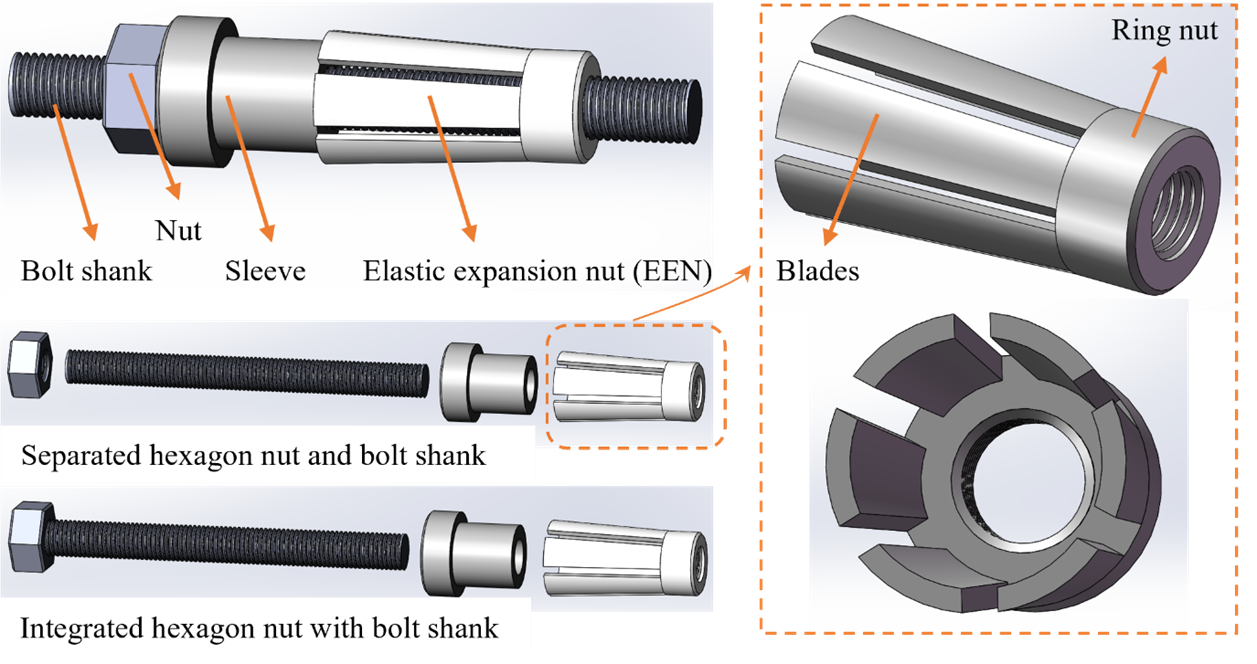

Figure 1. Proposed swift-constructed demountable blind bolt (SCDBB).

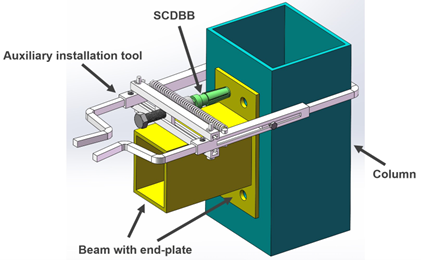

Figure 2. Auxiliary installation tool for SCDBB.

Figure 3. Experimental comparison with existing product.

Conclusions:

Corresponding works of the bolt design, fabrication procedure, and product supply chain determination have been completed. Considerable experimental and numerical investigations are also conducted. Test results from the scope of material properties to bolt behaviours indicate this proposed bolt can be regarded as a qualified product which can fulfil the requirements from relevant codes. At the same time, it also has satisfactory mechanical performance, and the improvement of bolt tensile strength compared with the existing product can be achieved appropriately.

References:

Han, X.-Z. and Chan, T.-M. (2022). “A swift-constructed elastic expansion nut and demountable blind bolt”. Patent No. ZL202220239181.3, Utility Model Patent, China National Intellectual Property Administration, The Government of People's Republic of China.

Han, X.-Z. and Chan, T.-M. (2023). “Auxiliary installation tool for blind bolt”, Patent No. ZL202223211533.3, Utility Model Patent, China National Intellectual Property Administration, The Government of People's Republic of China.

Han, X.-Z. and Chan, T.-M. (2023). “Swift-Constructed Demountable Blind Bolt for Fast Execution and Disassembling of SHS Connection”, Proceedings of the 10th European Conference on Steel and Composite Structures-EUROSTEEL2023. Amsterdam, The Netherlands, 12-14 September 2023.