Human-safe magnetorheological fibres set to transform smart wearable textiles

As the demand for advanced smart materials grows amid rapid developments in wearable technology, soft robotics and virtual reality, researchers are increasingly focused on creating textiles that combine flexibility, lightness, and intelligent responsiveness. In response to this global trend, a research team from PolyU has achieved a transformative breakthrough in smart materials, developing soft magnetorheological fibres that can flexibly deform and modulate their mechanical properties under a human-safe magnetic field.

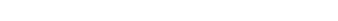

Led by Professor Tao Xiaoming, Director of the PolyU Research Institute for Intelligent Wearable Systems, Vincent and Lily Woo Professor in Textiles Technology and Chair Professor of Textile Technology of the School of Fashion and Textiles (SFT), the research team aimed to overcome two longstanding drawbacks of traditional magnetorheological materials: the heavy use of magnetic powders and potential health magnetorheological technology to fibre form while maintaining textile properties such as softness, flexibility, and breathability.

The team successfully fabricated soft magnetic polymer composite fibres – each just 57 micrometres in diameter – by uniformly dispersing magnetic powders in a low-density polyethylene matrix. These fibres offer precise control under low-strength, human-safe magnetic fields and can be spun into yarns and multi-layer fabrics for large-area, controllable deformation. This groundbreaking work, published in Nature under the paper titled “Vector-Stimuli-Responsive Magnetorheological Fibrous Materials”, received HK$62.37 million in funding under the Research Grants Council’s 2024/25 Theme-based Research Scheme.

The research team has created a range of innovative fabric materials utilising these new fibres, which provide unique responses that can be controlled directionally.

Unlike traditional smart materials that respond to scalar stimuli such as voltage or temperature, these newly developed textiles provide directionally controllable responses, enabling three innovative applications:

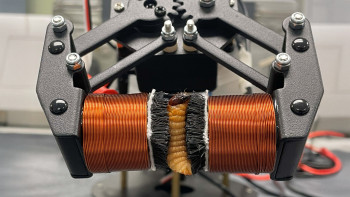

Flexible Smart Gripper

This gripper, controlled by an electric current, can flexibly grasp soft or irregularly shaped items, mirroring the dexterity of human fingers and minimising damage during manipulation.

Remote Emulation Haptic Finger Glove

Lightweight and comfortable, these gloves can replicate the textures and hardness of various objects, making them suitable for diverse applications, including remote surgical training and virtual fitting.

Active Ventilation and Thermal-Regulation Fabrics

These fabrics intelligently adjust air permeability through electronically controlled magnetic fields, enhancing wearer comfort in terms of temperature and moisture management.

Professor Tao emphasised that converting rigid magnetic devices into flexible alternatives lays a foundation for the next generation of soft robotics, electromagnetic devices, and wearable technologies. Dr Pu Junhong, Assistant Professor (Research) of SFT, highlighted that the use of mass production-ready materials and mature processing techniques ensures scalability and rapid industrialisation across fields such as medical rehabilitation, food production, and metaverse interaction.