Sampling the Moon’s Surface: Innovation, Precision and Reliability

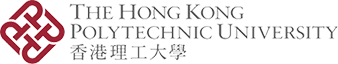

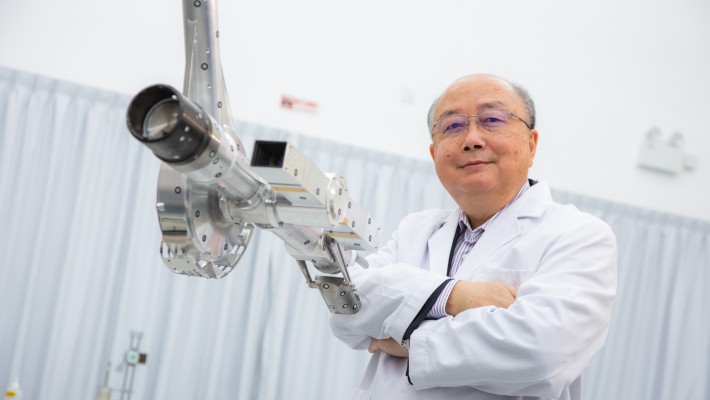

Collecting soil from the Earth may be as easy as pie, but it is highly complicated and difficult to collect lunar samples from the Moon, which is over 380,000 kilometers away from Earth. Yet on 17 December, China’s Chang’e 5 probe successfully returned to Earth after having collected almost two kilograms of lunar samples using robotic means. One of the core space instruments that facilitated the mission’s success was the “Surface Sampling and Packing System,” which was developed and manufactured by a 20-member team led by Professor Yung Kai-leung, Sir Sze-yuen Chung Professor in Precision Engineering, Chair Professor of Precision Engineering and Associate Head of the Department of Industrial and Systems Engineering, PolyU.

Check out the following video to learn about how the PolyU-developed instruments can overcome the sampling challenges under the extreme space and lunar environment:

With a proven track record of success in past national lunar exploration projects, the PolyU team beat many competitors and was tasked in 2011 to develop the system for lunar surface sampling, packaging and sealing. Professor Yung said the process of developing the system was extremely challenging because deep space exploration is full of uncertainties. Professor Yung explained, “Chang’e 5 adopted an unprecedented approach in collecting lunar samples. Our team had to develop a unique and novel system with our cutting-edge technology and innovative thinking to tackle the harsh space environment during the lunar exploration journey.”

Professor Yung shared his views on the development of innovation and technology, please watch the following video produced by the Innovation and Technology Bureau:

Building on previous studies of the lunar environment, the PolyU-developed Surface Sampling and Packing System includes two samplers that can withstand 200 °C for collecting samples of lunar regolith in loose and sticky form, two heat-resistant nearfield cameras for vision guidance during sample acquisition, and a packaging and sealing system for sealing the samples in a container. Bolstered with fundamental scientific theories and thousands of testing procedures, the mechanism and design of the system have taken into account all the possible scenarios that could take place during sample collection on the lunar surface.

Professor Yung shared that he and his team were “satisfied, excited and happy” witnessing the successful return of the samples. The highly sophisticated sampling and packing system has demonstrated the ability of the team to produce state-of-the-art technology that is innovative, precise and reliable. The Professor was delighted to be part of this groundbreaking accomplishment and to say proudly: “We did it!”

As one of the key members of the research team, Dr Robert W.M. Tam, Associate Director of PolyU’s Industrial Centre, was deeply honoured that this advanced innovation was developed and made in Hong Kong, at PolyU. He said, “We have the competence and expertise to reach this ultra-high standard of excellence and to satisfy the stringent requirements for space deployment.”

The completion of the Chang’e 5 mission marks the conclusion of China's current three-step lunar exploration programme of orbiting, landing and bringing back samples. Professor Yung and his team will compare the data collected on the moon with their design parameters and evaluate any improvements that may need to be made to the design for the Chang'e 6 mission, in which the PolyU sampling system will be adopted again. Looking to the future, Professor Yung is keen to obtain a quantity of the samples of lunar regolith for scientific research and to continue making significant contributions to the Nation’s space development.