Dr CHEN Zibin, Member of the Research Institute for Advanced Manufacturing (RIAM), and his teammates from PolyU, RMIT University and The University of Sydney, have created a new class of titanium alloys that are strong, ductile and sustainable, using oxygen and iron. These elements are abundant and cheaper than other metals.

Titanium alloys are advanced lightweight materials that are critical for industrial applications. α-β titanium alloys are the mainstay of the titanium industry. However, the presence of oxygen can make titanium brittle, and iron can segregate into defect flecks, thus limiting the strength and ductility of α-β titanium-oxygen-iron alloys.

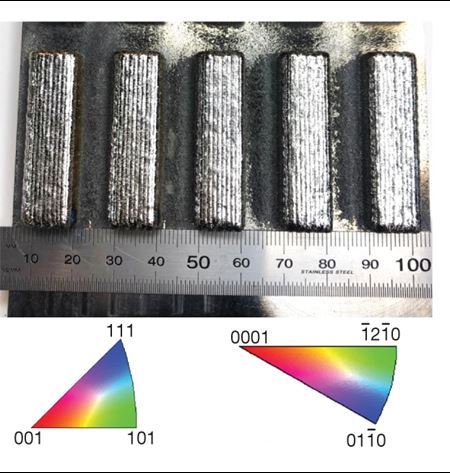

To address this issue, the team integrated additive manufacturing (AM) including net-shape or near-net-shape manufacturing in the design of alloys that exhibit outstanding tensile properties. The simplicity of the AM process and the use of abundant oxygen and iron elements make these α-β titanium-oxygen-iron alloys attractive for a variety of applications. Unlike the Kroll process, which is a widely used yet highly energy intensive method to produce titanium, the AM method transforms the off-grade titanium sponge into high-performance titanium alloys. Hence, this method is a more economical and environmentally friendly solution. The results have been published in Nature. (https://www.nature.com/articles/s41586-023-05952-6)