Injecting PolyU technology innovations into the Chinese textiles and apparel industry

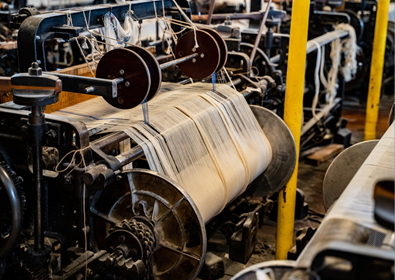

The Hong Kong Polytechnic University (PolyU) is a leading institution for fashion and textiles education and research in Asia and across the globe. The University’s fashion and textiles journey can be traced back to 1957, when the Hong Kong Technical College, predecessor of PolyU, founded the Department of Textiles Industries, becoming the first institution to provide textiles education at the post-secondary level.

Six decades later, PolyU’s venture into fashion and textiles has achieved resounding success. The University upgraded its Institute of Textiles and Clothing to the School of Fashion and Textiles (SFT), and has produced numerous practical applications and innovations blending textiles and design with advanced technologies including electronics, artificial intelligence and 3D printing.

In recent years, the University’s expanding efforts in fashion and textiles development have led to the establishment of new research units, including the PolyU–Xingguo Technology and Innovation Research Institute in February 2025. Taking the helm of the new mainland translational research institute is Prof. FAN Jintu, Lee Family Professor in Textiles Technology and Chair Professor of Fiber Science and Apparel Engineering in SFT. In this Issue, Prof. Fan talks with PAIR about leveraging PolyU’s research strengths in the development of the fashion and textiles industry in mainland China.

Making the fashion and textiles industry greener, smarter and more functional

The fashion and textiles industry has always been dynamic, with the continual introduction of new technologies. The two research units led by Prof. Fan—the Research Centre of Textiles for Future Fashion (RCTFF) and the new PolyU–Xingguo Technology and Innovation Research Institute—represent PolyU’s latest strategies to expand the University’s research innovation and translation capabilities in the field. RCTFF and the new institute have different but complementary foci, the former on interdisciplinary and translational research and the latter on technology transfer.

“Sustainability, digitalisation and functionality are three major drivers of innovation in the fashion and textiles industry.”

Sustainability, digitalisation and functionality, according to Prof. Fan, are three major drivers of innovation in the field. “The fashion industry is a big contributor to environmental pollution, producing tonnes of clothing waste, and most of it ends up in landfills. As such, many large brands are incorporating ESG (environmental, social and governance) into their businesses,” he said.

The past few decades have seen waves of technological revolution impacting operations in many industries, and the fashion and textiles sector is no exception. “In the 1980s, clothing companies were already introducing information, digital and computerised technologies into manufacturing and design. The 1990s witnessed a surge of interest in the deployment of robotics in the field. The rise of large language models in recent years has stirred a new wave of artificial intelligence applications in the fashion industry,” Prof. Fan explained. He further elaborated on the quest for functionality in the field: “Planet-wide challenges such as global warming and the energy crisis have driven scientists to develop functional clothing that keeps us cool and comfortable, hence reducing our reliance on air conditioning and saving energy. Functional clothing products are also very important in healthcare.”

Finding the most strategic location: Expanding the PolyU research and development pipeline in China’s textile hub

The PolyU–Xingguo Technology and Innovation Research Institute, located in Xingguo county, Ganzhou city, Jiangxi province, China, focuses on cutting-edge research and innovation in the textile and fashion technology, intelligent wearable systems, smart manufacturing and sustainability. The institute aims to support the development of Xingguo into a regional and national hub for manufacturing and innovation.

“Mainland China has the world’s largest textiles industry in terms of production, exports and retail.”

Mainland China has the world’s largest textiles industry in terms of production, exports and retail. The new institute signifies PolyU’s priority focus on textiles research development in mainland China. “Currently, there is not much clothing and garment manufacturing in Hong Kong,” Prof. Fan remarked. “There are about 800 manufacturers registered or headquartered in Hong Kong, including some highly successful and world-leading brands. Their innovation pods are situated locally, but their factories operate in mainland China or Southeast Asia.”

He emphasised that PolyU’s mainland translational research institute is strategically important: “Setting up a research facility in mainland China is conducive to PolyU’s fashion and textiles research. It enables PolyU researchers to collaborate directly with manufacturers there in applying PolyU technologies to industry challenges and enhancing their business competitiveness. The industry in mainland China possesses the equipment and facilities that PolyU researchers need in order to scale up and incubate their research.”

Situated in Ganzhou city, Xingguo county is about two and a half hours from Hong Kong by high-speed rail. Establishing the new research institute in Xingguo allows it to take full advantage of the county’s economic opportunities and geographic features. “The Ganzhou Municipal Government and Xingguo County Government in Jiangxi province have been very proactive in initiating and setting up this institute to drive the growth of the local economy there,” Prof. Fan shared.

He went on to describe the changing landscape of the textiles industry in China: “Dongguan city used to be one of the largest hubs for textiles in China. As labour costs in these cities have risen, a number of garment businesses have decided to move their factories either to other countries such as Vietnam, or to the northern regions of China. However, many companies would rather relocate to Ganzhou city because it is geographically closer to Dongguan. This allows companies to retain some manufacturing operations in Dongguan, while moving the more labour-intensive and less technologically demanding operations elsewhere. Xingguo county is a fairly attractive option because of its convenient location and generally low labour and material costs.”

This tectonic shift in the Chinese textiles industry is giving rise to a new economy. “Xingguo has a large population, making it easy for factories to recruit workers. When businesses relocate, they do not send their existing workers to the new location to do low-paying jobs; instead, they recruit locals at lower wages. This way, Xingguo residents can stay in town to work and look after their families,” Prof. Fan said.

University-industry partnership: A win-win situation

In his new capacity as the Director of the PolyU–Xingguo Technology and Innovation Research Institute, Prof. Fan hopes to achieve a “win-win” situation for the university and the local government. “From the university’s perspective, the new institute is for research development, for example, leveraging the facilities and equipment in Xingguo to scale up PolyU technologies and potentially create spin-off companies there,” he noted. “From the local government’s perspective, the new institute is for industrial and economic development. They have clear plans for developing a new industrial ecosystem in Xingguo, where manufacturing companies and research facilities are housed in a single industrial complex.”

Creating impact through research is a goal pursued by many universities. Prof. Fan views the two research units he leads as being complementary in terms of research impact. He described the different focus areas of the units: “RCTFF focuses on applied fundamental research, while the new institute focuses on technology transfer. Of course, RCTFF can also carry out technology transfer activities, such as licensing, so that PolyU technologies can be applied to enterprises and businesses. In contrast, the new institute in Xingguo is more inclined towards incubation, that is, establishing new start-ups together with the local government.”

He further explained that RCTFF’s future development will place more emphasis on technology development and commercialisation, and the centre will evaluate existing efforts and identify specific research areas in which the team may achieve the most success.

Roadblocks to technology transfer

In the transfer of technology from lab to market, obstacles are often encountered. Intellectual property (IP) protection and the technology transfer ecosystem are two major challenges, according to Prof. Fan.

“Intellectual property protection and the technology transfer ecosystem are two major challenges.”

“There are very few technologies that cannot be imitated,” he observed. “When you come up with a technological innovation and obtain a patent, it can sometimes be difficult to protect it. This is because competitors may try to observe and copy the technology. IP protection is easier to achieve if a developer also owns the manufacturing pipeline. In this way, patents can be protected because the technology is directly used in manufacturing.”

He continued to explain the need for Hong Kong universities to expand research beyond the region: “Currently, Hong Kong’s manufacturing industry is very small in scale, and opportunities to apply new technologies for mass production are limited. Our ecosystem is not conducive to innovation. As a result, researchers are increasingly interested in collaborating with industry in mainland China. However, many challenges arise in cross-border collaboration due to differences in culture, policies and practices.”

Finding your focus and adapting to evolving research trends

Prof. Fan’s research focuses on improving the understanding of interactions among the human body, clothing and the environment and, on that basis, developing fibrous materials and fashionable clothing with enhanced functional performance.

The fashion and textiles industry adapts quickly to changing market and technological trends. When asked if these fast-paced dynamics require researchers to change foci from time to time, Prof. Fan accentuated the importance of interdisciplinary research. “My research involves instrumentation, computational modelling, biomimetics, nanotechnology and artificial intelligence, as well as psychology. Because of the interdisciplinarity of my research, although my research focus has not changed much over the years, I have become adaptive to new technologies and market trends. This mindset is essential to fashion and textiles research and development.”

Please put at least one valid content allocate to this component.

Please put at least one valid content allocate to this component.

Please put at least one valid content allocate to this component.

Please put at least one valid content allocate to this component.

Please put at least one valid content allocate to this component.

Please put at least one valid content allocate to this component.