Steel Matters

Improving welding technology and understanding atmospheric corrosion will enhance the safety and sustainability of Hong Kong buildings

Steel is essential for sturdy buildings and long-lasting infrastructure. To make steels even stronger, PolyU researchers have uncovered key enhancements.

High-strength steels including S690 and S960 offer excellent strength-to-weight ratios, reducing steel usage and construction costs in multi-storey buildings and long-span bridges. According to Professor Chung Kwok-fai from PolyU’s Department of Civil and Environmental Engineering, who is also the Director of the Chinese National Engineering Research Centre for Steel Construction (Hong Kong Branch) (CNERC), although S690 and S960 have been produced worldwide since the 1990s, their use remains limited, partly owing to persistent challenges around welding and quality assurance. Improper welding can compromise the material, and affect the integrity and performance of structures built with them.

PolyU’s welding technology for S960 steel was applied in a footbridge at the Fanling North New Development Area.

Addressing welding challenges

A CNERC research team led by Professor Chung has been addressing challenges that fabrication with high-strength steel presents. They conducted extensive tests on the S690 welded sections, finding that controlling heating and cooling processes is critical to minimising microstructural changes in heat-affected zones of welded joints. While some heat is unavoidable, basing welding parameters on joint geometry can help ensure minimal heat input. These findings have improved the use of S690, exemplified by its application in the Double Arch Steel Bridge of the Cross Bay Link in Tseung Kwan O, setting a global industry precedent.

The research team has taken the solution further to minimise or even eliminate adverse effects of welding when applying ultra-high strength S960 steel. In a practical setting, the solution has been adopted in a footbridge at the Fanling North New Development Area – Fanling Bypass Eastern Section. The new welding technology enables the use of thinner and fewer steel materials, thereby reducing the self-weight of the footbridge, and hence, the number of foundation piles required. This, in turn, has led to decreased carbon emissions and enhanced sustainability. This project marks Hong Kong’s first public works using S960 steel.

Tackling atmospheric corrosion

While these advances in high-strength steel technology are promising, understanding how corrosive sea air affects steel is also essential, especially in coastal areas like Hong Kong, where protecting infrastructure from damage by salt in the air is vital.

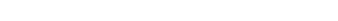

Since 2010, Professor Chung’s team has conducted air exposure studies at seven separate locations in Hong Kong. The results show that carbon steel corrodes at a rate of 30 to 40 micrometres each year, whereas the zinc and galvanised steel used outdoors corrode more slowly at 3 micrometres per year. Buildings near Victoria Harbour are particularly susceptible to corrosion, which can weaken structures and pose safety risks.

Mr Yuen Ka-fai (left)

| Professor Chung Kwok-fai (right)

|

To combat these challenges, PolyU PhD student Mr Yuen Ka-fai has developed a real-time corrosion monitoring system under Professor Chung’s supervision. Between 2020 and 2024, he collected approximately 40,000 datasets a year from all seven sites, employing electrochemistry, remote sensing, and AI to assess the impact of corrosive chemicals and climate factors on steel structures.

The monitoring system was implemented at the InnoCell Building in the Hong Kong Science Park, and also at Nam Cheong 220, which was the first structural steel social housing project in Hong Kong to use modular integrated construction (MiC) technology.

Hong Kong’s unique climate makes atmospheric corrosion a serious issue. This study will help develop more effective maintenance strategies, extending the

lifespan of buildings while reducing costs.

~ Professor Chung Kwok-fai.

Outdoor exposure tests determine atmospheric corrosion rates of different steel alloys.