Super-fast large-area economical marine reclamations for housing and infrastructural developments

Hong Kong has a long history of marine reclamation and related technological applications. As part of the Hong Kong- Zhuhai-Macau Link Project, wo artificial islands were reclaimed using sandfill and vertical drains with sandfill surcharge surrounded by 120 steel pipe piles (22 m in diameter and 50.5 m in length). In the reclamation of Hong Kong Airport Runway 1 and Runway 2, the project was accomplished by dredging and removing all Hong Kong Marine Deposits (HKMD), which had caused marine environmental problems. For the new Third Runway, all HKMD were kept in situ and surrounded by seawalls constructed on deep cement mixed (DCM) soil foundations. Imported sandfills (or crushed stones) were used to fill the eclaimed area. Vertical drains with preloading were used to improve the HKMD. However, there is a severe shortage of sand for marine reclamation projects in Hong Kong. The cost of crushed stones is high and production of crushed stones takes time. Therefore, it is imperative that an alternative reclamation method be identified—one that is economical, efficient and sustainable for Hong Kong.

Led by Ir Prof. Yin Jian-hua, Management Committee Member of the Research Institute for Land and Space (RILS) and Chair Professor of Soil Mechanics at the Department of Civil and Environmental Engineering (CEE), the research team has developed and implemented an innovative technique using horizontal band drains alongside a vacuum preloading method. This approach may facilitate the reuse of dredged sediment as fill material in future reclamation projects in Hong Kong.

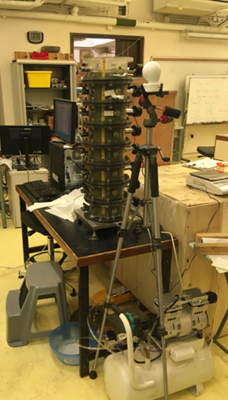

Systematic research efforts, from experimental testing and theoretical modelling to engineering application, are underway. Specifically, three physical model tests are now being conducted to simulate the whole process of implementing the new soft soil improvement method,

including the dredging process, self-weight consolidation process and fast consolidation process by vacuum preloading with prefabricated band drains. Preliminary test results have clearly demonstrated that the new method is capable of reducing water content and increasing soil

strength in an efficient and economical way. For example, in a large-scale plane strain physical model, the average water content of dredged sediment decreased from 220% to 76%, while the shear strength of sediment increased from almost zero to 27 kPa at the bottom of the physical

model within 100 days of applying vacuum pressure.

To facilitate theoretical modelling, a new simplified Hypothesis B method was proposed. The new method has been verified by engineers as being accurate and easy to use. It can be used to predict the settlement of HKMD or other soft soils in layers and installed with/ without drains subjected to staged loading-unloading-reloading and even vacuum loading. Moreover, a prototype field trial is ongoing in a testing pit (base size of 12 m x 8 m and depth of 3.5 m) in Tung Chung in collaboration with the Civil Engineering and Development Department of the HKSAR government, AECOM and Build King-Samsung C&T Joint Venture to prove the practicality and constructability of the technique in the field. To follow up on these efforts,

a combined mechanical-chemical method, which incorporates binder stabilisation using industrial wastes and vacuum preloading with prefabricated band drains at the same time, will be evaluated as a potential sustainable approach to marine reclamation.