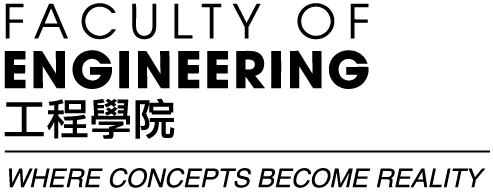

Netshape Manufacturing Technology Unit

- Promote and Introduce the Technology

- Consultancy

- Feasibility Study

- Production and Installation

- Assist in sourcing Funding and securing Application

- Assist in carry out heavy-duty super-high pressure hydroforming test

- Assist in carry out pilot fabrication of different metal sponges

- YXLON FF35 CT computed tomography system

- 2500 tons huge-duty super-high-pressure hydroforming system (PUG-2500)

- 4-axis CNC engraving machine

- CREPOW Classtig 200AD Welding Machine

- Self-developed 3-in-1 bike frame tester

- 30 tons manual-type hydraulic press

- Self-developed drop fall impact tester

- 160 Ton AIDA-Japan Cold-forging Mechanical Press

- 160 Ton OMERA-Italy Double Action Hydraulic Press

- 250MPa Hydroforming Attachment with Computer-controlled Console

- Desktop Hydroforming Testing Unit

- Computer-controlled Gas Pressure Bugling Tester

- Overhauled Hille Swift Forming Tester

- 100 kN MTS Uniaxial Tensile Machine (temporary located at CD003)

- Carbolite-UK High Precision Heating Ovens

- Induction Heater

- FLIR Thermovision System for Temperature Distribution Measurement

- High-Temperature PL Controllers

- PLC Enhanced Gear-profile Rolling Machine

Research areas & activities

- Tube and Sheet Hydroforming

- Sheet and Bulk Forming

- Fine Blanking

- Formability Prediction, Damage Modeling and Process Simulation

- Laser Processing and Die Casting

- Precision Tooling and Progressive Stamping

- Profile Rolling

- Special Forming Equipment Design and Manufacture

Publications

Selected journals and conference papers within recent 5 years:

- Xianzheng Lu and LC Chan, "Numerical Simulation for Thermal and RT Forming Light Sheet Materials Using a New Combined Model of M-K Theory and Shear Localization Criterion". The International Journal of Advanced Manufacturing Technology, Vol. 83, No. 1 (2016), pages 357-363

- XZ Lu and LC Chan, Micromechanics-based damage model for failure prediction in cold forming, Materials Science and Engineering A, Vol. 690 (2017), pages 120-131

- LC Chan, Non-destructive testing for microstructure assessment in applied research and development, in YXLON CT user conference 2016, Hamburg, Germany, 26-27 Oct 2016, YXLON International GmBH (Oct 2016)

- LC Chan and XZ Lu, "Multiscale Analysis of Deformation in Metal Damage Prediction", The 23rd International Conference on Plasticity, Damage, and Fracture, Puerto Vallarta, Mexico, 3-9 Jan 2017, NEAT PRESS, Maryland, USA, pages 61-63 (Jan 2017) ISBN 978-0-9911654-6-9(print)

- LC Chan, XZ Lu, KM Yu, Multiscale Approach with RSM for Stress–strain Behaviour Prediction of Micro-void-considered Metal Alloy, Materials & Design, Vol. 83 (2015), Pages 129-137

- TF Kong, LC Chan, Prediction of Multipreform Shapes in Warm Forming with Experimental Verification, JOM, 2015, 67(2): 436-449.

- SS Wong, LC Chan, CP Lai, WY Ip, LH Chau, In-vitro and In-vivo Degradation Evaluation of Mg-based Alloys for Biomedical Applications, Journal of Material Science and Technology Research, Vol. 1, no. 2 (2015), Pages 1 – 9

- CP Lai, LC Chan, Finite-element Modelling of Thermal Forming of Ti-TWBs with Experimental Verification, Key Engineering Materials, Vol. 626 (2015), Pages 518-523.

- LC Chan, CP Lai, LH Chau, WY Ip, Biocompatibility Study of Magnesium-based Metal Sponge, Proceeding of the 9th International Conference on Porous Metals and Metallic Foams (Metfoam 2015), page 218, 31 Aug-2 Sept 2015, Barcelona, Spain.

- SS Wong, WY Ip, LC Chan, CP Lai, In vivo Study on the Biodegradation Behaviours of Mg-Based Alloys for Orthopaedic Application, Proceeding of the 27th European Conference on Biomaterials (ESB2015), 30 Aug-3 Sept 2015, Krakow, Poland

- XZ Lu, LC Chan, Construction of Representative Volume Element for FE Simulation of Bulk Deformation of Stainless Steel Using X-Ray Computed Tomography Approach, TMS2015 Supplemental Proceedings, Pages 485-490, 15-19 Mar 2015, Orlando, USA.

- LC Chan, Net Shape Forming Technologies for Gear Profile Rolling and High-Strength Tube Hydroforming, Proceeding of the BIT 4th Annual World Congress of Advanced Materials (WCAM2015), Page 301, 27-29 May 2015, Chongqing, China

- XZ Lu, LC Chan, Data Acquisition in 3D Tomography for Multiscale Microstructure Model Construction under Uniaxial Compression, MS&T2015 Supplemental Proceedings, Pages 561-566, 4-8 Oct 2015, Ohio, USA.

- TF Kong, LC Chan, Bulk-Forming Simulation of Bimetallic Watchcase Components, JOM, Vol. 66, no. 10 (2014), Pages 2145-2155.

- LC Chan, XZ Lu, Material Sensitivity and Formability Prediction of Warm Forming Magnesium Alloy Sheets with Experimental Verification, International Journal of Advanced Manufacturing Technology, Vol. 71, no. 1-4 (2014), Pages 253-262.

- LC Chan, CP Lai, SS Wong, WY Ip, Corrosion and Hydrogen Evolution Improvement of Biodegradable Mg-based Alloy for Orthopedic and Implant Applications, 2nd International Conference on BioTribology (ICoBT 2014), 11-14 May 2014, Toronto, Canada (Electronic version)

- SS Wong, CP Lai, WY Ip, LC Chan, Zin’s role in Mg-Zn-Mn Alloys for Orthopedic Applications, 2014 Annual Meeting of the Society for Biomaterials, 16-19 Apr 2014, Denver, CO (Electronic version)

- LC Chan, XZ Lu, Numerical Simulation on Forming Behavior of Magnesium Alloy at Elevated Temperatures with Experimental Verification. Advanced Materials Research, Vol. 677 (2013), Pages 179-182.

- LC Chan, TF Kong, Numerical Simulation and Experimental Study on Profile-rolling Process for Micro-teeth Components, Advanced Materials Research, Vol. 677 (2013), Pages 252-255.

- CP Lai, LC Chan, Microstructural Analysis of Stress Relieving on the Thermal Deformation Behaviors of Titanium Tailor-welded Blanks, Advanced Materials Research, Vol. 677 (2013), Pages 169-172.

- LC Chan, Numerical Determination of Sheet Metal Forming Limit Based on a New Combined Model of M-K Theory and Shear Localization Criterion, Advanced Materials Research, Vol 330 (2013), Pages 821-825.

- WKR Kot, LC Chan, Determination of Loading Paths in Warm Hydroforming Reinforced Quadrilateral Tubular Components, Materials and Manufacturing Processes, Vol. 29, no. 1 (2013), Pages 32-36.

- WKR Kot, LC Chan, In-Process Visualisation for Deformation Monitoring and Analysis of Sheet Metal Forming Processes, Advanced Materials Research, Vol 677 (2013), Pages 384-387.

- LC Chan, KM Au, KM Yu, FEM-CT Integrated Design for Multiscale Damage Analysis of Hydroformed Magnesium-based Alloy Tubular Product, NDT & E International, Vol. 56 (2013), Pages 38-47.

- CP Tsui, CY Tang, HY Wang, LC Chan, Damage Prediction of a Graded Porous Biocomposite Implant Using the Finite Element Method, Proceedings of the First International Conference on Damage Mechanics, Pages 293-296, 25-27 Jun 2012, Belgrade, Sebrian.

Ir. Prof. L. C. Chan (Unit Director and Labs-in-charge)

Tel: (852) 2766 6634

Fax: (852) 2362 5267

Email: lc.chan@polyu.edu.hk

Dr. T. F. Kong (Project Associate)

Tel: (852) 2766 6573

Fax: (852) 2766 6771

E-mail: tf.kong@polyu.edu.hk

Dr. C. P. Lai (Project Associate)

Tel: (852) 2766 6614

Fax: (852) 2766 6771

Email: cp.lai@polyu.edu.hk