- TECHNOLOGIES & SOLUTIONS

- Technologies

- Solutions

INDUSTRY 4.0 AND INTERNET OF THINGS

The first industrial revolution that began in the 18th century ushered in the age of steam and the accompanying developments. Starting from the 1870s, the world was entering the second industrial revolution—electrification. For the third industrial revolution in the 1940s and 1950s, the main goal was automation. Since 2011, with the development of popular domains, such as, big data and cloud computing, industrial revolution has entered a phase of transitioning from automation to smart processes1. In 2011, the concept of 'Industrie (Industry) 4.0' was first proposed by three professors at the Hannover Messe in Germany. In April 2013, the German government officially adopted 'Industry 4.0' as one of the ten Future Projects in Germany's 'High-Tech Strategy 2020'. Subsequently, policies such as 'Advanced Manufacturing' in the United States, 'Made in China 2025' in China, 'Factory 2050' in the United Kingdom, and 'Productivity 4.0' in Taiwan were introduced. These policies emphasise the importance and necessity of industrial transformation to reform, and the conversion to smart processes is the core of 'Industry 4.0'.

1馮甜,「工業4.0对制造業带来的變革和思考」,博客,2017 年 12 月 29 日。

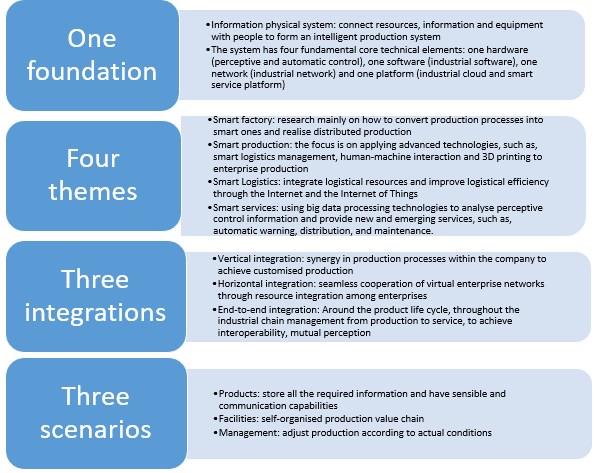

Different from the previous three industrial revolutions, 'Industry 4.0' is no longer limited to invention itself. What it emphasises to a greater degree is the integration of technologies - combining information and communication technologies with the virtual world of cyberspace to create a highly flexible and personalised model of survival and to restructure the industrial chain. 'Industry 4.0' is based on the Cyber-Physical System (CPS), with four 'smarts' (smart factories, smart manufacturing, smart logistics and smart services) as the theme, with three major integrations (vertical integration, horizontal integration and end-to-end integration) as the goals to be achieved, three scenarios (products, facilities, management) are proposed. Figure 1 will list out each point1.

Figure 1: Main content of 'Industry 4.0'

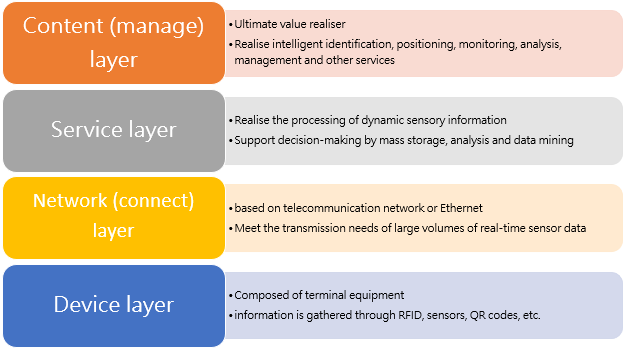

Figure 1: Main content of 'Industry 4.0'Industry 4.0 points to a new phase for the current development and IIoT is a mean to achieve smart manufacturing. The IIoT emphasises the use of IIoT technologies in the industrial sector and is welcomed by governments, enterprises and organisations. The architecture of a typical industrial IIoT system consists of four different processing layers: the device layers, the network (connection) layers, the service layers, and the content (manage) layers2. The functions at each level are shown in Figure 2. The technologies involved in each layer will be introduced one by one later.

2張程、楊冬菊, 「物聯網系列二:體系架構」

Figure 2: Architecture of an Industrial IoT System

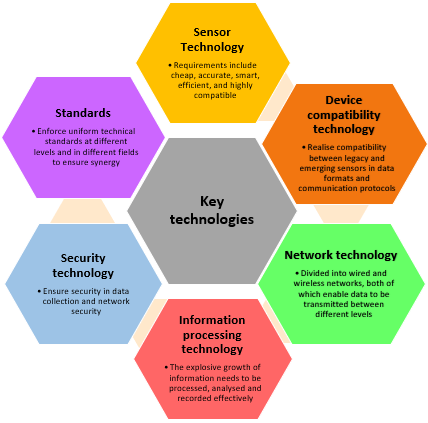

Figure 2: Architecture of an Industrial IoT System Figure 3: Six key technologies of IoT

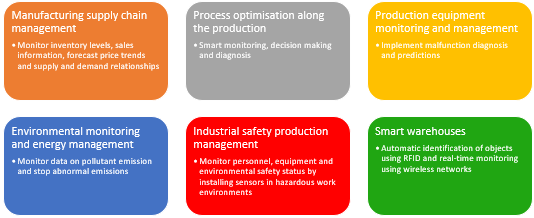

Figure 3: Six key technologies of IoT Figure 4: Applications of IIoT

Figure 4: Applications of IIoT