- TECHNOLOGIES & SOLUTIONS

- Technologies

- Solutions

Manufacturing

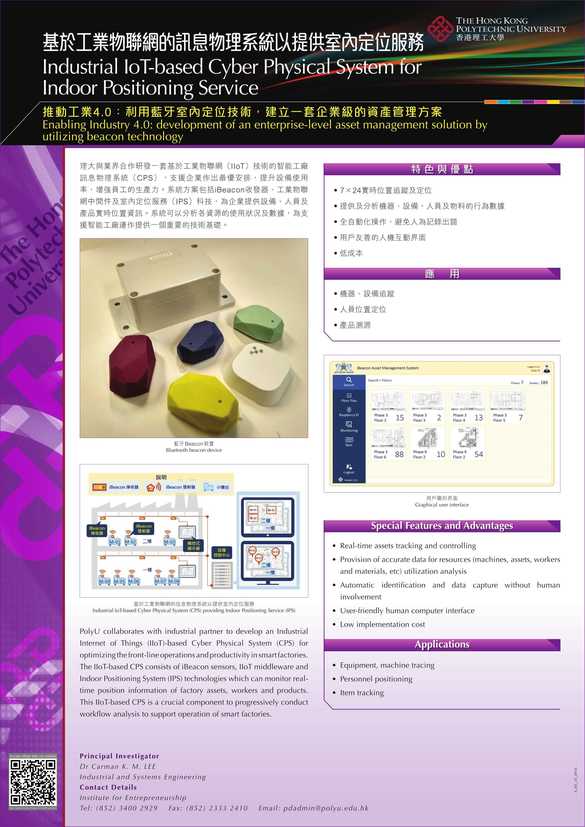

Industrial IoT-based Cyber Physical System for Indoor Positioning Service

PolyU collaborates with industrial partner to develop an Industrial Internet of Things (IIoT)-based Cyber Physical System (CPS) for optimizing the front-line operations and productivity in smart factories. The IIoT-based CPS consists of iBeacon sensors, IIoT middleware and Indoor Positioning System (IPS) technologies which can monitor realtime position information of factory assets, workers and products. This IIoT-based CPS is a crucial component to progressively conduct workflow analysis to support operation of smart factories.Industrial IoT and Big Data Analytics based Predictive Maintenance System

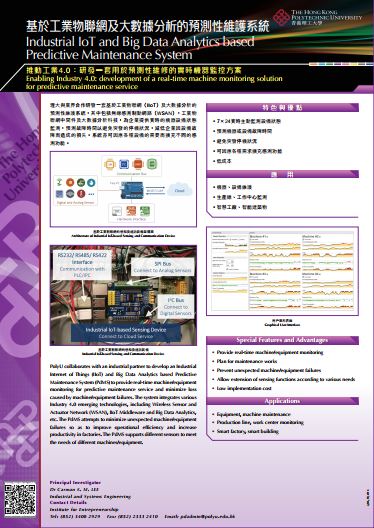

PolyU collaborates with an industrial partner to develop an Industrial Internet of Things (IIoT) and Big Data Analytics based Predictive Maintenance System (PdMS) to provide real-time machine/equipment monitoring for predictive maintenance service and minimize loss caused by machine/equipment failures. The system integrates various Industry 4.0 emerging technologies, including Wireless Sensor and Actuator Network (WSAN), IIoT Middleware and Big Data Analytics, etc. The PdMS attempts to minimize unexpected machine/equipment failures so as to improve operational efficiency and increase productivity in factories. The PdMS supports different sensors to meet the needs of different machines/equipment.Device-to-Business (D2BTM) Technology and Applications

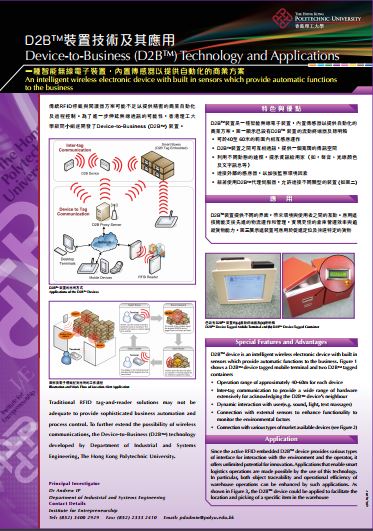

Traditional RFID tag-and-reader solutions may not be adequate to provide sophisticated business automation and process control. To further extend the possibility of wireless communications, the Device-to-Business (D2BTM) technology developed by Department of Industrial and Systems Engineering, The Hong Kong Polytechnic University.RFID-enabled Asset Management System for Manufacturers

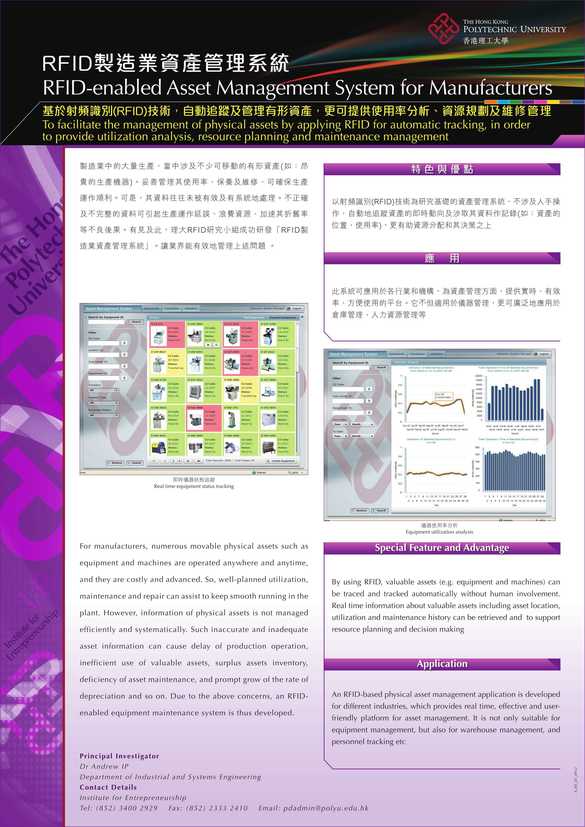

For manufacturers, numerous movable physical assets such as equipment and machines are operated anywhere and anytime, and they are costly and advanced. So, well-planned utilization, maintenance and repair can assist to keep smooth running in the plant. However, information of physical assets is not managed efficiently and systematically. Such inaccurate and inadequate asset information can cause delay of production operation, inefficient use of valuable assets, surplus assets inventory, deficiency of asset maintenance, and prompt grow of the rate of depreciation and so on. Due to the above concerns, an RFIDenabled equipment maintenance system is thus developed.

BACK TO TOP