Innovative multi-tier smart inspection system safeguards bridges

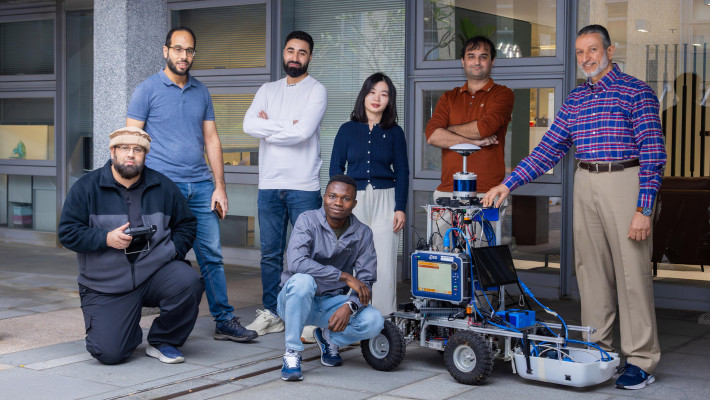

Hong Kong’s densely packed transport network places significant pressure on its bridges, making structural safety a top priority. In response, a research team at PolyU, led by Professor Tarek Zayed from the Department of Building and Real Estate, has developed an intelligent bridge inspection system supported by the Smart Traffic Fund. This innovative system can detect cracks and hidden structural defects that are not visible to the naked eye.

This multi-tier system has already been deployed across 11 local bridges, merging PolyU’s proprietary non-destructive testing (NDT) technologies with advanced AI models. This integration has reduced inspection time by half and increased accuracy to 80%, setting the stage for broader implementation throughout the city.

Precision bridge inspection with drones, GPR, and IRT

At the heart of this innovation are three cutting-edge technologies: drones, ground-penetrating radar (GPR), and infrared thermography (IRT). Together, these tools enhance the inspection process by gathering extensive data from both the surface and subsurface of bridges. The use of AI for automated analysis yields unprecedented accuracy and efficiency in identifying structural issues. This development directly addresses the limitations of traditional visual inspection methods in Hong Kong, which are often labour-intensive, subjective, and prone to overlooking critical subsurface defects, such as rebar corrosion, which can lead to unnecessary road closures.

Key challenges in bridge inspection include detecting small surface cracks, uncovering hidden rebar corrosion, and identifying concrete deterioration. To tackle these issues, the PolyU team has developed AI-driven solutions that utilise drone-enabled visual inspection, GPR, and IRT. Their self-developed deep convolutional neural network (CNN) model—Smart Bridge Deck Efficiency (SBDE)—can accurately detect cracks even in low light conditions. Additionally, an automated GPR model achieves over 98% precision in locating rebars and corrosion zones. The optimum thermal gradient threshold (OTGT) system for IRT adapts to environmental conditions, allowing for the precise identification of delamination. This comprehensive approach facilitates faster, more accurate bridge assessments, contributing to enhanced safety and efficiency in infrastructure management.

“This hybrid system— for surface and subsurface defects—enhances both the efficiency and accuracy of bridge inspection through an integrated, AI-powered approach,” said Professor Zayed. “We have also standardised inspections with a five-point severity scale to facilitate diagnosis and prioritise repairs. The comprehensive SBDE tool thoroughly assesses bridge conditions based on data collected from various sensing devices.”

The team is currently working with government and industry partners to apply the system in regular bridge inspections, advancing smarter infrastructure management and ensuring Hong Kong’s bridges remain safe and reliable.

Implemented on 11 local bridges, the system replaces traditional visual inspections with a suite of advanced tools, including drones, GPR, and IRT.