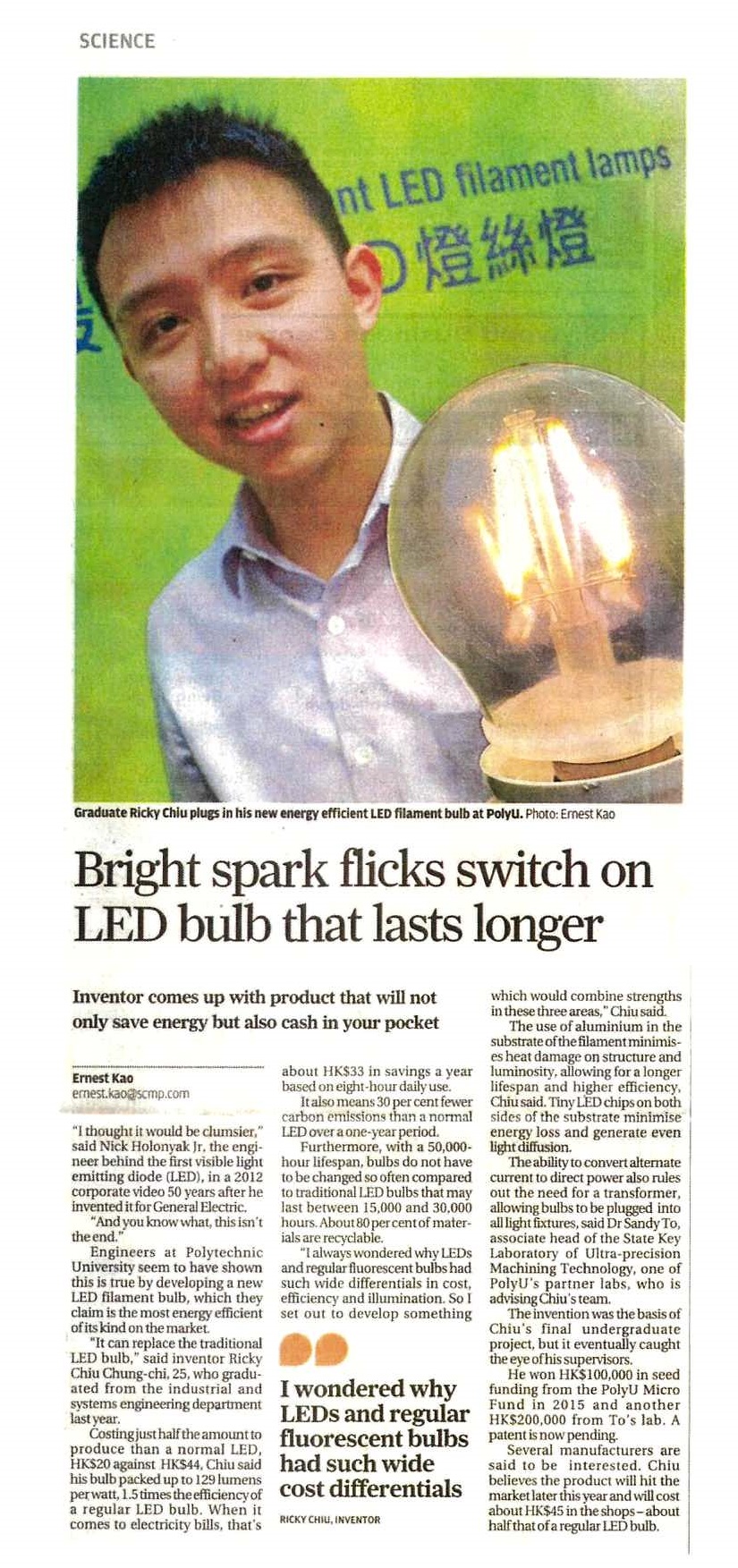

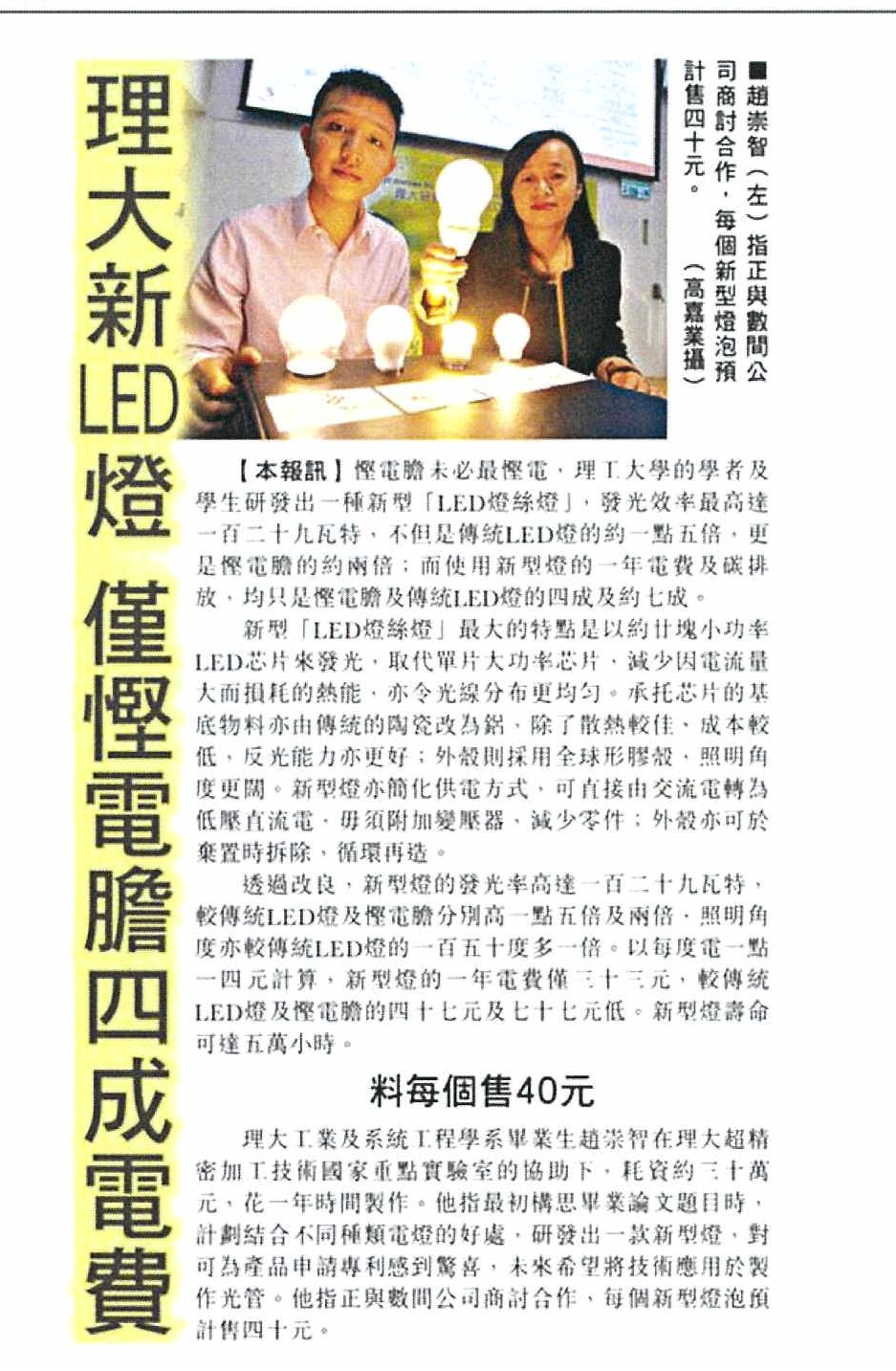

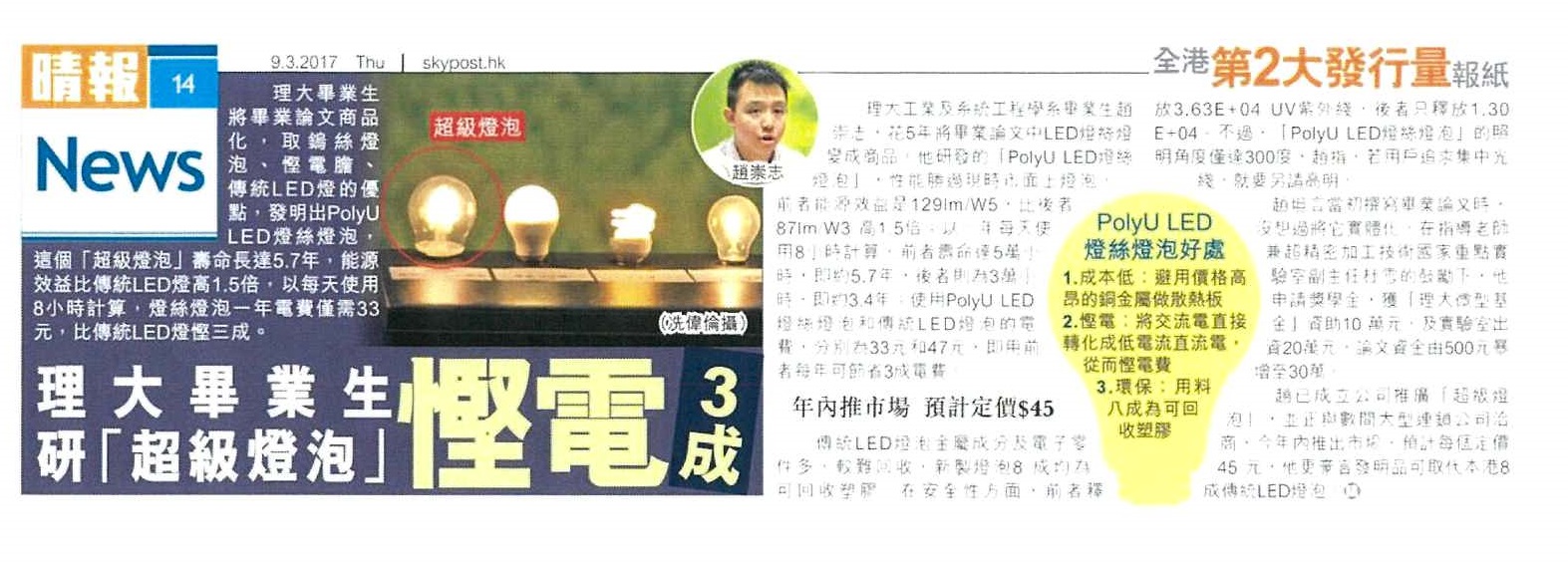

A research team of State Key Laboratory of Ultra-precision Machining Technology (Partner Laboratory in The Hong Kong Polytechnic University) and PolyU students has successfully developed the most energy-efficient Light Emitting Diode (LED) filament technology with a luminous efficacy of 129lm/W, which represents 1.5 times the efficacy of traditional LED lamps, surpassing all other general lighting tools available in the market. In 2015, PolyU Micro Fund awarded a seed fund of HK$100,000[1] to the student team and it is expected that the product can be launched this year.

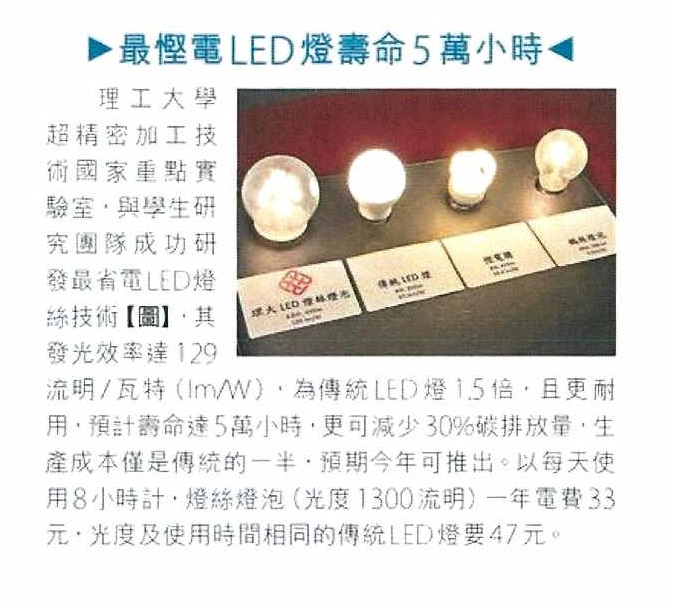

This LED filament technology has excellent energy efficiency. Based on the assumption of a daily operation of eight hours, a PolyU's LED filament bulb with lumen of 1300lm costs HK$33[2] of electricity tariff per year, and contributes to 22kg of carbon dioxide emission yearly. In comparison, a traditional LED lamp costs HK$47 of electricity tariff and 31kg of carbon dioxide emission yearly with the same lumen and conditions, which means that the new technology can reduce carbon dioxide emission by 30%. Besides, the new technology enables an expected lifetime of 50,000 hours, with only half of the production cost of traditional LED lamps.

Thanks to its energy-saving and long lifetime features, LED lighting contributes significantly to sustainable development. However, the limitations of traditional LED lamps, including high production cost and narrow beam angle have affected its popularity. The LED filament technology developed by PolyU has not only achieved breakthrough in the areas of energy efficiency, lifetime, and production cost, but it also has other advantages including:

- Wide beam angle: 300-degree, parallels to that of incandescent bulb;

- Comparably high colour rendering index (CRI): Enables original colour projection of objects as if they are in natural light;

- Less UV light emission; and

- More environmental friendly: Absence of harmful chemicals, and consists of less electronic components, and 80% of recyclable materials.

These breakthroughs are made possible by the following technology advancement:

- Using Aluminium as substrate material

LED chips are sensitive to heat. Heat diminishes its luminosity and speeds up the drop of lumen, and therefore heat flow design of substrate is crucial to the lifetime of LED lamps. Instead of ceramic and sapphires, Aluminium, with good thermal conductivity, high reflectivity and affordable price, is chosen as the substrate material, to achieve longer lifetime and higher lumen at a lower cost. - Mounting LED chips of small power on both sides of substrate

The larger the power (Watt) of a LED chip is, the higher the electric current it needs, leading to more energy loss. In PolyU's LED filament lamp, LED chips with large power are replaced by many tiny LED chips with small power which are mounted on both sides of the substrate. This design will reduce energy loss and generate even light diffusion, without affecting luminosity. - Applying PolyU's advanced injection moulding technology

Hemispherical plastic case of LED lamps made with traditional plastic moulding method limits beam angle. Applying advanced injection moulding technology developed by PolyU Advanced Optics Manufacturing Centre, a seamless and transparent spherical plastic case is produced to make 300-degree beam angle possible. - Enhancing power supply

PolyU LED filament lamp converts AC (alternate current) to low current DC (direct current) directly without dealing with the voltage, and hence reduces components required and simplifies circuits, enhancing reliability and efficiency of the lamp.

The patent application of this new technology has been filed and the prototype design is completed. In future, the team will conduct various tests and obtain certifications for market launch.

Footnotes:

[1] The amount of seed fund offered by PolyU Micro Fund has been increased to $120,000 since 2016

[2] HK$1.14 per kWh

香港理工大學 (理大) 超精密加工技術國家重點實驗室與學生研究團隊成功研發市場上最省電LED (發光二極管) 燈絲技術,其發光效率達129 流明/瓦特 (lm/W),約為傳統LED 燈的1.5倍,能源效益超越現時市場上的通用照明產品。2015年「理大微型基金」撥出十萬元[1]予該學生團隊,預期有關產品可於今年推出。

理大研發的LED 燈絲燈技術具優越的能源效益,以每天使用8小時計算,燈絲燈泡 (光度1300流明) 一年所需電費僅為33 港元[2],碳排放量為22 公斤CO2e。而相同光度、相同使用時間情况下,傳統LED 燈卻要耗電47港元,碳排放量為31 公斤CO2e,故可新技術可減少30% 的碳排放量。不但如此,理大LED燈絲燈預計壽命長達50,000 小時,生產成本僅為傳統LED 燈的一半。

LED 照明產品省電長壽,對可持續發展有顯著貢獻。但是,傳統LED燈仍然存在不少缺點和局限,如生產成本高、照明角度狹窄等等,影響其市場普及。理大研發的LED燈絲技術除了在能源效益、壽命和生產成本等方面取得突破性的進展,還包括以下優點:

- 照明角度廣闊─可與鎢絲燈泡一樣覆蓋300度;

- 顯色指數高─接近日光的顯色指數令物件尤如呈現在自然光下;

- 釋出紫外線低;及

- 更加綠色環保—不含有害化學物質、所用電子零件少,可回收材料達八成。

以上突破性進展和優點源自如下的技術創新:

- 採用金屬鋁作為基底

LED 晶片對熱力敏感,熱力會使其光度減弱及加速衰退,因此基底的散熱設計成為影響LED 燈壽命的關鍵因素。理大團隊選取具優秀散熱性能和良好光反射性、價格相宜的金屬鋁作為基底材料取代陶瓷或藍寶石,以延長壽命、增加光度,同時降低生產成本。 - 將多片小功率LED晶片置於基底兩面

單片LED 晶片的功率越大,其所需電流量越大,能量損耗就越多。在理大LED 燈絲燈的設計中,研究人員以多片小功率的LED 晶片取代單片大功率晶片,平均置於基底的上下兩面,在輸出同等光度情況下,可以降低能量損耗,同時令光線分佈均勻。 - 採用理大先進塑膠注塑成型技術

傳統的塑膠注塑技術只能塑造半球型燈罩,限制照明角度。理大團隊應用理大先進光學製造中心特有的先進塑膠注塑成型技術,造出無縫和高透光的塑膠近球形燈頭罩,達至300度空間照明角度。 - 優化供電方法

理大的LED 燈絲燈將交流電直接轉換為低電流直流電,取代變換電壓的供電方式,簡化電路,減少燈絲燈所需電子零件,提升可靠性及效率。

該技術發明專利申請已獲受理,研究團隊已經完成原型設計,未來會進行進一步的測試、申請各項產品認證及市場推廣。

註:

[1] 自2016年起,「理大微型基金」的資助額已提高至十二萬港元

[2] 以每度電1.14港元計

(Source: PolyU website)

Online media coverage:

Oriental Daily News - http://orientaldaily.on.cc/cnt/news/20170309/00176_021.html

On.cc - https://goo.gl/39ZzHC

SCMP - https://goo.gl/uzVuR9

Ming Pao Daily News - (1) https://goo.gl/QnEHQA (2) - https://goo.gl/zs8zc2

Commercial Radio - https://goo.gl/whtwHV

Sing Tao Daily - https://goo.gl/y1OL0u

am730 - https://goo.gl/hzIQmq

HK Economic Times - https://goo.gl/uFWukv

HK Economic Journal - https://goo.gl/pXvOnU

Ta Kung Pao - http://www.takungpao.com.hk/hongkong/text/2017/0308/65179.html

Wen Wei Po - http://paper.wenweipo.com/2017/03/09/ED1703090001.htm

HK Commercial Daily - http://www.hkcd.com.hk/content/2017-03/08/content_3631846.htm

Yahoo HK - (1) https://goo.gl/8OUWxP (2) https://goo.gl/g0kPXr (3) https://goo.gl/RWwymS

新華社 - http://news.xinhuanet.com/gangao/2017-03/08/c_1120591242.htm

Sina HK - https://goo.gl/ePLcvm

新浪新聞 - http://news.sina.com.cn/o/2017-03-08/doc-ifychavf2060116.shtml

Sina.tw - http://news.sina.com.tw/article/20170308/20983052.html

Asia Pacific Daily - http://zh.apdnews.com/XinHuaNews/603632.html

亞太日報 - http://www.niuson.com/XinHuaNews/603632.html

香港新聞網 - http://www.hkcna.hk/content/2017/0308/551310.shtml

星島環球網 - http://ed-china.stnn.cc/finance/2017/0308/408328.shtml

半導體照明網 - http://lights.ofweek.com/2017-03/ART-220001-8120-30112122.html

Benzinga.com - https://goo.gl/acYw5p

Kuam News - https://goo.gl/QYD2B2

88iv - http://www.88iv.com/sc/hot_news_detail.html?id=1703090609

| Topics | Research | Staff Achievement | Student Achievement |

|---|---|

| Department of Industrial and Systems Engineering |

You may also like

.png?bc=f1f1f1&h=325&w=620&rev=cb613a8233c945f9bcf46a3a30ea3027&hash=8C94A27234497978A2C2B7EC7C326748)

.jpg?bc=f1f1f1&h=325&w=620&rev=7d7e6eeef5f84608a89c17c9fedb8eb0&hash=B5451426EBC02E66CA43191873728286)