To learn about the industrial partners and their Co-op projects, please click on each company board.

|

| www.aerovision.com.hk |

Aerovision Technology Limited is a fast-growing company located in Hong Kong Science Park. We aspire to use the latest technologies to improve service standards and work efficiency for aviation and other industries, providing premier solutions to security, engineering, safety, and daily operational problems encountered. We provide special purpose-built AI and IoT solutions to enhance the effectiveness of operational activities in terms of time, labour, materials, and reliability. If you love challenges and are willing to contribute to making technological advancements, you are most welcome to join us!

Work location: Unit 321, 3/F, Building 2W, No.2 Science Park West Avenue, Pak Shek Kok, N.T., Hong Kong

Project Description/Work Duties:

- Preparation of engineering drawings

- Preparation of BOM for the procurement process

- Preparation of project documentation for submission to clients

- Assist in the preparation of the project’s operation and maintenance training materials

|

| www.atihk.com |

We specialize in air system products, special design and build projects, technical support and product development. Our market sectors cover transportation, industrial and commercial developments, air purification and flow controls, and entertainment facilities.

Work location: Tsuen Wan

Project Description/Work Duties:

- Provide supports to engineering manager on products development including design calculations, drawing preparations, cost estimations, etc.

- Coordinate with manufacturers on material sourcing and production requirement

Requirements:

- Good communication and inter-personal skills

- Hand on experience on AutoCad or other softwares for technical drawings preparation

- Good command of written and spoken English and Chinese

- Construction Industry Safety Training Certificate holder

|

| www.ael.hk/ |

Associated Engineers, Limited (AEL) is a leading multidisciplinary engineering consultancy specializing in Airport Engineering, Environmental Engineering, Infrastructure Engineering, Logistics and Automation and Engineering Services. With nearly six decades' experience in turn-key engineering projects, AEL provides complete solutions from consulting, design, manufacturing, project management, commissioning and after-sales maintenance.

Work location: 23/F Stelux House, 698 Prince Edward Road East, San Po Kong, Kowloon

Project Description/Work Duties:

- Assist in conducting preliminary studies of engineering projects and participating in the subsequent marketing and tendering works

- Write technical specification drafts, request proposals and technical information from third party suppliers and vendors and evaluate and compare such proposals

- Produce drawings and technical submission for engineering equipment/systems, monitor the manufacturing process and supervise the site works

- Participate in the project implementation, operation, and maintenance work

|

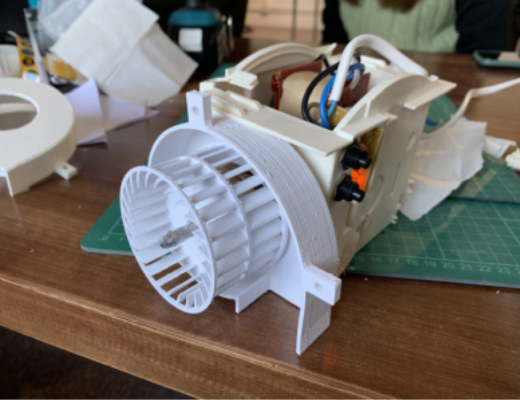

| www.bissell.com |

The BISSELL goal is to help you improve the ways you take care of your home, right down to the microscopic irritants. Since 1876, we've spent years developing cleaning tools designed to keep your living environment up to the highest standards.

Work location: Shenzhen

Project Description/Work Duties: Research the plastic material selection for Uvac product

Requirements: Mechanical Engineering background

| https://www.gewcorp.com/ |

G.E.W International Corporation Limited is seeking a highly skilled and motivated Research Engineer to join our dynamic R&D department. As a Research Engineer, you will play a crucial role in developing innovative technologies and advancing the performance of our espresso machines. If you are passionate about coffee, have a strong background in engineering, and enjoy working in a collaborative environment, this is the perfect opportunity for you.

Founded in 1961, G.E.W. is a leading electrical appliance manufacturer with extensive experience in producing heating appliances and coffee products. We specialize in one stop product development solution from design concept to product shipment, to our worldwide customers. We also develop ODM products which can cater for the requirements of different customers. We focus on innovation and protection of IP. Our innovation office in Hong Kong is purposefully built for focusing on product research and patent application. Our main product lines included household , semi-professional and commercial range for coffee machine, coffee grinder and toasters.

Work location: Kwun Tong

Project Description/Work Duties:

- Conduct research and development activities to enhance the performance, efficiency, and functionality of our espresso machines and coffee grinders

- Design and prototype new components, systems, and features for our products with the rest of the team, considering factors such as brewing temperature, pressure, extraction time, and water flow

- Perform experiments, collect and analyse data, and present findings to support decision-making processes

- Stay up-to-date with the latest advancements in espresso machine technology, coffee brewing techniques, and industry trends

Requirements:

- Background knowledge and strong passion of espresso machine components, brewing principles, and coffee extraction is a plus

- Proficiency in CAD software for designing and prototyping components

- Experience with data analysis and statistical tools to interpret experimental results

- Excellent problem-solving skills and ability to think creatively to overcome technical challenges

- Strong communication and collaboration skills to work effectively in a cross-functional team environment

- Fluent in spoken and written Chinese and English

|

| https://lansonplace.com/ |

We are a subsidiary of Wing Tai Properties Limited, a premium developer of quality residential, commercial, industrial, serviced apartments, and boutique hotel projects. Since being listed in 1991, Wing Tai Properties Limited has set the standards of creativity, Asian hospitality, and elegant property design and construction that have become a trademark also seen in Lanson Place.

Your Place Lanson Place

Leave the hustle and bustle behind and step into a place that feels like home. A sanctuary of serenity and French-inspired sophistication. A place to pause, connect and reconnect. Your place, that's Lanson Place.

Set amidst vibrant Causeway Bay, Lanson Place will re-emerge in the first quarter of 2024, timed to perfectly align with a positive market recovery, as a leading luxury boutique hotel in Hong Kong, a member of Small Luxury Hotels. Designed with meticulous detail by world-renowned Interior Designer Pierre-Yves Rochon, it will confidently showcase the personality of Lanson Place and its unique blend of modernity and French flair.

Work location: 133 Leighton Road, Causeway Bay

Project Description/Work Duties:

- Assist in conducting routine inspections of the hotel's mechanical, electrical, and plumbing systems to ensure their proper functioning.

- Support the engineering team in performing preventive maintenance tasks, including checking and replacing filters, lubricating equipment, and inspecting safety devices.

- Assist in responding to and resolving guest requests and complaints related to engineering issues promptly and efficiently.

- Learn how to operate, maintain, and repair the hotel's heating, ventilation, and air conditioning (HVAC) systems.

- Gain knowledge of the hotel's fire safety systems and assist in conducting regular fire safety drills and inspections.

- Assist in monitoring the hotel's energy consumption and identifying opportunities for energy conservation and efficiency improvements.

- Learn how to maintain and repair the hotel's pool, spa, and fitness center equipment.

- Support the engineering team in maintaining an inventory of spare parts, tools, and supplies and ensure their proper storage and organization.

- Gain familiarity with the hotel's building automation system (BAS) and assist in troubleshooting and resolving any issues.

- Observe and adhere to all safety regulations and procedures to ensure a safe working environment.

Requirements: Team player and willing to learn

|

|

| www.raymondfinance.com/html/about.html |

An ODM/OEM manufacturer in home appliances industrial, mainly focusing on personal care, home environmental and beverage related products. Established for 60 years in Hong Kong and own a factory in mainland China.

Certified as ""High Tech Enterprise"" in China, we are dedicated to spend our efforts in core R&D. Throughout the in-depth cooperation and product development with our customers, we have developed and brought to the market very successful novel products, including the award from "Red Dot".

Work location: Nansha GuangZhou, Mainland China

Project Description/Work Duties:

- Station in factory during week days. Company will offer transportation between HK and Mainland China

- Be an assistant in our R&D department or a project assistant/engineer of our on-going development projects

- In R&D department, main duty is the principle research

- In Project Development department, main duty is assist the project manager in project development management

Requirements:

- Basic skills in CAD software operation (preferably SolidWork)

- High competence in Oral English and English writing

|

| www.rec-eng.com/ |

REC is one of the Hong Kong’s largest engineering companies. We are engaged in every aspect of electrical and mechanical engineering services, including electrical installation, air-conditioning, fire prevention and fighting, plumbing and drainage, building automation systems, and engineering maintenance services. Our service covers the full project life cycle from initial electrical and mechanical design through installation to testing and commissioning and operation and maintenance, providing a one stop shop service to our clients.

We also excel in environmental engineering projects such as sewage treatment plant, pumping station, electrochlorination, and automated refuse collection system. Furthermore, our chemical engineering branch serves both public and private clients with their water treatment expertise.

Work location: Units A-D, 15/F, Goodman Kwai Chung Logistics Centre, 585-609 Castle Peak Road, Kwai Chung, N.T., Hong Kong

Project Description/Work Duties:

- Assist the development of design innovation tools / methods for construction sites / projects

- Tools / method suggestion to support project teams

- Join innovation meeting to understand the needs of others project teams

|

| https://www.towngas.com/en/Home |

Founded in 1862, The Hong Kong and China Gas Company Limited (Towngas) was Hong Kong's first public utility. Today, we are one of the largest energy suppliers in Hong Kong, operating with world-class corporate management and leading-edge business practices. For the past years, Towngas has been growing with Hong Kong, evolving from the simple gas company supplying fuel for street lamps to our current leading position in the energy industry in the greater China region.

Work location: Quarry Bay

Project Description/Work Duties:

Position 1 (Ref. no.: CIMSD-2/Co-op/2024)

- Assist in product development and testing, IoT development and application

- Assist in data analysis, reports preparation and PPT creation

- Complete school related project

- Conduct market research

Position 2 (Ref. no.: PMSD-1/Co-op/2024)

- Provide support to engineers in preparing quotations and supporting documents

- Conduct market research

- Being an assistant to join site walk and site meeting

- Assist engineers in supervising the kitchen cabinet installation of local residential projects

Requirements:

Position 1 (Ref. no.: CIMSD-2/Co-op/2024)

- Undergraduate with major in Mechanical / Product Engineering or relevant discipline

- Engineering knowledge, Product Design, Basic Computer Programming (e.g. Arduino)

- Creative and well-organized

- Innovative, positive and willing to learn

- Knowledge in 3D CAD design and drawing (e.g.Solidworks)

- Basic computer programming

Position 2 (Ref. no.: PMSD-1/Co-op/2024)

- Undergraduate with major in Product Design Engineering or relevant discipline

- Knowledge in 3D CAD design and drawing (e.g.Solidworks)

- Proficient in MS Office (Excel, Word and Power Point)

- Willing to visit construction sites occasionally to understand site work conditions (under the supervision of Engineers)

- Well-organized with good analytical skill

- Good interpersonal and communication skills

- Green Card (Mandatory Basic Safety Training Courses) holder will be advantage

|

| Parklane.com.hk |

A international hotel brand - A Pullman hotel, with 820 rooms at CWB, 3 dining restaurants & banquets function meeting rooms, car parking spaces and multiple shop tenants - Ikea

Work location: Causeway Bay

Project Description/Work Duties: To assist project manager to carry out guestroom renovations, assist Assistant chief engineer for hotel E&M operations and maintenance, improvement work and design to solve guest problem

Requirements: Creativity on problem solving, self motivation for improvement work and enhancement to provide "better" service to guests

|

| www.time-medical.com |

Time Medical is an innovator in the medical diagnostic imaging industry aiming to bring advanced, accessible, and affordable imaging to all populations.

Work location: Shatin and Tai Po

Project Description/Work Duties:

- medical robotic and MRI development project

- Responsible for turning 2D design concepts into manufacturable 3D models

- Prepare and maintain product specification and other documentation

- Work closely with vendors, follow up product development from prototype to manufacturing stage

- Other duties as assigned