What resources we have?

| Tests | Equipment | Applicability for Construction Concrete/Timber Waste | Applicability for Consumer Plastic Waste | Applicability for Food/Metal Waste |

|---|---|---|---|---|

| Carbon/Mineral content | Thermogravimetric Analyzer | Y/Y | N | Y/Y |

| Viscosity of suspension | Rheometer (RST CC) | Y/N | N | Y/N |

| Viscosity of suspension | Rheometer (CP-5000) | Y/N | N | Y/N |

| Buildability and setting of plastomer | Penetration Resistance Tester | Y/N | N | Y/N |

| Water content | Oven (normal) | Y/Y | N | Y/Y |

| Water content | Oven (vacuum drying) | Y/Y | Y | Y/Y |

| Weight of the samples | Balance (to 0.1 mg) | Y/Y | Y | Y/Y |

| Compression strength | Compression Machine for Mortar | Y/Y | Y | Y/Y |

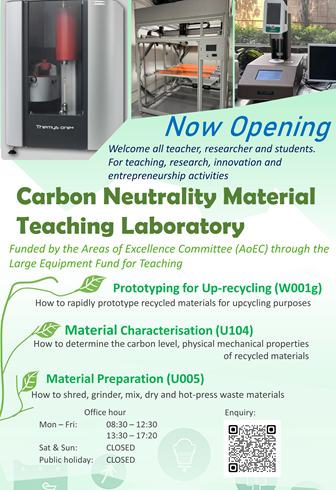

Specification

Thermogravimetric Analyzer (TGA) with Auto Sampler

Location: U104

Process: Testing

Material: Construction Materials and Wastes, Polymer

Specification:

Model: KEP SETARAM THEMYS ONE+

Major specification:

- Measuring ranges: +/- 1000 mg or +/- 200 mg

- Auto sampler with a 32-position carousel

- Furnace configuration up to 1150 ℃

- Temperature scanning rate: 0.01 to 100 ℃/min

Application:

- Inorganically mineral qualitative and quantitative determination

- Organic carbon content determination

Wance Compression Machine for Mortar

Location: U005

Process: Construction Materials

Material: Multiple Materials

Specification:

- Maximum test force: 300kN (compressive strength); 10kN (flexural strength)

- Net distance between two columns: 330mm

- Loading speed: 2400 ± 200N/s (compressive strength); 50 ± 5N/s (flexural strength)

Rheometer (RST CC)

Process: Construction Materials

Material: Multiple Materials

Specification:

- Speed ranging from 0.0001 to 80 rpm in both clockwise or counter-clockwise

- Torque ranging from 0-10000 Nmm with a resolution of 0.05 Nmm and accuracy better than 0.02Nm

- Specimen volume of 3L with inner diameter of 165 mm and height of 175 mm

- Special proximity sensor with automatic stop function

Rheometer (CP-5000)

Process: Construction Materials

Material: Multiple Materials

Specification:

- Measurement range: 0.6-540,000,000 mPa.s

- Accuracy: ±1% (of current range)

- Repeatability: 0.2%

- Automatic temperature control: Optional temperature range of -60~300°C

- Sample volume: 0.03~0.15ml (cone-plate system); 2.1~25ml (coaxial cylinder system)

Penetration Resistance Test

Location: U005

Process: Construction Materials

Material: Construction Materials

Specification:

- In compliance with ASTM C403/C403M-16

- Maximum penetration force of 1000 N

- Indication error within -1% to 1%

- Minimum graduation value of 0.1 N

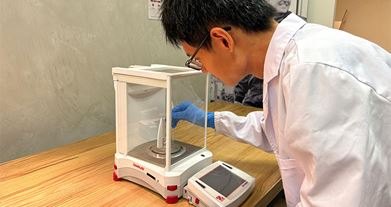

Electronic Balance (ten thousandth)

Location: U104

Process: Construction Materials

Material: Multiple Materials

Specification:

- Model: BSA120.4

- 120g range

- ±0.1mg

- Tray size with a diameter of 90mm

Drying Oven (normal)

Location: U005

Process: Construction Materials

Material: Multiple Materials

Specification:

- Provided for desiccation, torrefaction, wax-melting and sterilization in laboratory

- Uniform distribution of air temperature and forced-air convention

- Temperature range RT+10~200°C

- Temperature stability ±1°C

- Chamber volume: 136L

- Interior dimension (W x D x H, mm): 550 x 450 x 550

Drying Oven (vacuum drying)

Location: U104

Process: Construction Materials

Material: Multiple Materials

Specification:

- Model: BPZ-6033LCB

- Temperature control range: RT+10-200 ℃

- Inner container size: 320 × 320 × 320 mm

- Program-controlled drying monitoring with automatic ventilation at end of process

Contact Us

Apart from the Carbon Neutrality Lab, IC also provides varies of equipment and support (Testing, Training, and Consultation) that meet your need. Kindly consult our IC staff for more details on collaboration.

Sustainable Material Characterisation Laboratory

Opening Hours: 08:30 to 17:20, Monday to Friday

Venue: U104

Enquiries

LIU Ming-kit Kenny 廖銘傑

Engineering Manager (Construction and Infrastructure Team)