PolyU Introducing Engineering Innovations and Game-changing Rules for Its Red-brick Campus

Red brick architecture is one of the notable features of The Hong Kong Polytechnic University (PolyU). However, as the campus has been established for many years, constant maintenance and repair are required to render the building's external walls safe.

In this regard, PolyU allocates a budget each year for external wall inspections and timely repairs throughout the campus in order to prevent wall tiles from falling off due to aging.

In the past, due to limitations in engineering technology, examiners would use infrared instruments to inspect the external walls remotely, identifying the approximate locations at risk of loose tiles before tapping manually on each of them for verification. This approach heavily relied on the experience and judgment of the workers, not to mention there was no standardized qualification framework within the industry.

It is the belief of PolyU that, considering the on-campus population density and usage rate, as well as financial concerns, a more precise and rigorous detection system coupled with verification is necessary to ensure the safety of students, staff, and campus users; moreover, it is not ideal to use the traditional method alone to inspect external walls.

Surveying and Inspection Accuracy Significantly Boosted by Combining Intelligent Software with Traditional Methods

Wallace (middle) is taking a group photo in the laboratory of LSGI with CFSO’s Mr. T. C. Chik, Senior Facilities Manager (left) and Mr. Kevin Cheung, Technical Manager (right).

With the density of high-rise buildings in Hong Kong, it is incredibly challenging to conduct photogrammetry with infrared thermography (IRT) inspections for external walls of buildings in narrow streets. Measurement techniques and angles can significantly affect the accuracy of the results.

To tackle this issue, PolyU’s Campus Facilities and Sustainability Office (CFSO) invited Ir Dr. Wallace Lai, Associate Professor and Associate Head (Teaching) of the Department of Land Surveying and Geo-Informatics (LSGI), to act as a technical consultant for the inspection of external walls in the preventive maintenance project. Wallace and his PhD student Lydia Chiu and postdoc Dr. Janet Sham applied the Infrared Image Analysis Software (IIAS), a self-developed technology, to correct the originally imperfect infrared images' angles and adjust the thermal imaging tones based on the actual temperature of the walls, by inputting the shooting distance and the visible range of the infrared thermal imaging camera. Consequently, a spectrum of risks of delamination can be identified through the varying shades of color in the images.

IIAS is also equipped with image stitching technology, which can combine infrared images of different sizes and extremely low pixels into a complete elevation image plan, aiding workers in planning the repair details.

Additionally, Wallace's team introduced the mechanical hammer tapping (MHT) test to replace the traditional method of manual hammer tapping. By analyzing the sound produced by the tapping hammer, this mechanical method can identify locations and areas of delamination in the external finishes.

Before conducting the MHT test, the team needs to establish some testing parameters based on the specific project requirements, such as the sensitivity of the hammer, the material of the tiles, and the force and frequency of the tapping. Only in this way can the test yield meaningful data. "Otherwise, if the parameters are too strict, the entire building may appear to be defective," said Wallace.

The team believes that by combining traditional IRT inspections with IIAS and the MHT test, the most accurate surveying results can be obtained.

Before conducting the MHT test, the team needs to establish testing parameters for hammer-tapping. As per this project, the area where a 3-millimeter gap is detected between the concrete and the tiles is designated as having delamination risk.

Experiment before Implement

Currently, IRT inspections for external wall surveys fall within the scope of accreditation1 under the Hong Kong Laboratory Accreditation Scheme (HOKLAS). However, as a research institute, PolyU aims to take advantage of this opportunity to conduct on-campus verification of the new technology.

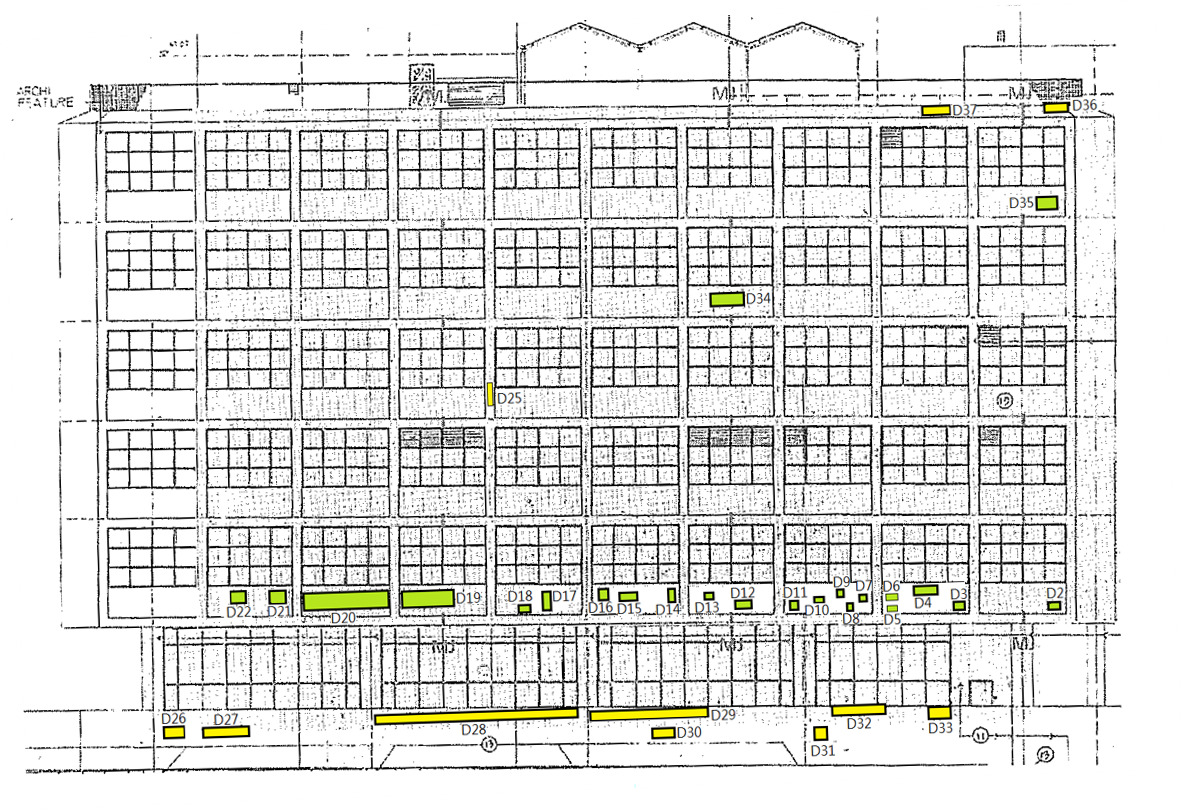

For this purpose, the team conducted experiments on the south-facing external wall of the Communal Building at PolyU.

The experiments were divided into four groups:

1) Using only traditional IRT inspections for external walls (conducted by a testing company).

2) Using the data from the IRT inspections mentioned above, combined with IIAS developed by LSGI to enhance the results.

3) An HOKLAS-accredited testing company using the traditional method of manual hammer tapping only.

4) An HOKLAS-accredited testing company using MHT only.

After each group completed the inspection, the team removed the tiles and substrate at 20 locations identified as defective in the test report from the fourth method, in order to verify whether there were delaminations between the tiles/substrate and the concrete wall, and to compare the findings of the 4 methods to determine their respective accuracy. A total of 20 locations with actual delamination and risks of tiles falling off were detected.

The survey results are as follows:

Method 1) – 2 locations with delamination were identified;

Method 2) – 6 locations were identified, while the remaining 14 locations with delamination were not successfully identified due to environmental factors;

Method 3) – 17 locations were identified;

Method 4) – 20 locations were identified in total, meaning it successfully identified all delaminations, which is an encouraging result.

In terms of cost, for a calculation based on 1,000 square meters, the manual hammer tapping test costs HKD 25,000, while the MHT test costs HKD 120,000. With such a significant cost difference in mind, Mr. T. C. Chik, Senior Facilities Manager (Technical Services Section 3) of the CFSO, believes that the accuracy of the survey is of utmost importance, given the high population density on the PolyU campus and the paramount importance of external wall safety.

"If we only consider the cost and choose to conduct manual hammer tapping tests, the accuracy of the inspection will be questioned in the event of future accidents. We may need to erect work scaffolding and re-inspect, which will be more time-consuming and cause disturbances to many teaching activities," he explained.

Thanks to the introduction of new technology and the emphasis on safety, the CFSO won the Gold Award in the PolyU Occupational Safety and Health Excellence Award 2023 with this project. PolyU is also delighted to have won the Bronze Award at the 22nd Hong Kong Occupational Safety and Health Award in the OSH Enhancement Program Award category for the “Preventive Maintenance Program Against Falling Tiles of Building Façade”.

After completing the survey procedures, the team removed the tiles and substrate at the locations identified as defective to verify the accuracy of surveys done by each group.

Wallace demonstrates to the technical staff how to operate the MHT equipment.

Using the IRT inspection technology, combined with the IIAS developed by LSGI, the locations with delamination are identified during the inspections.

Method 4 was adopted, which involves using traditional IRT inspections for external walls, enhancing the results with IIAS, and an inspection using a combination of manual hammer tapping and MHT, which accurately identifies all locations with delamination.

With the technology of infrared detection coupled with IIAS that rectifies distorted images, it is possible to identify a spectrum of risks of tiles falling off the external walls of different buildings on the PolyU campus by looking into the colour contrasts.

3D Surveying Images Enhance Efficiency of Underground Culvert Construction at PolyU

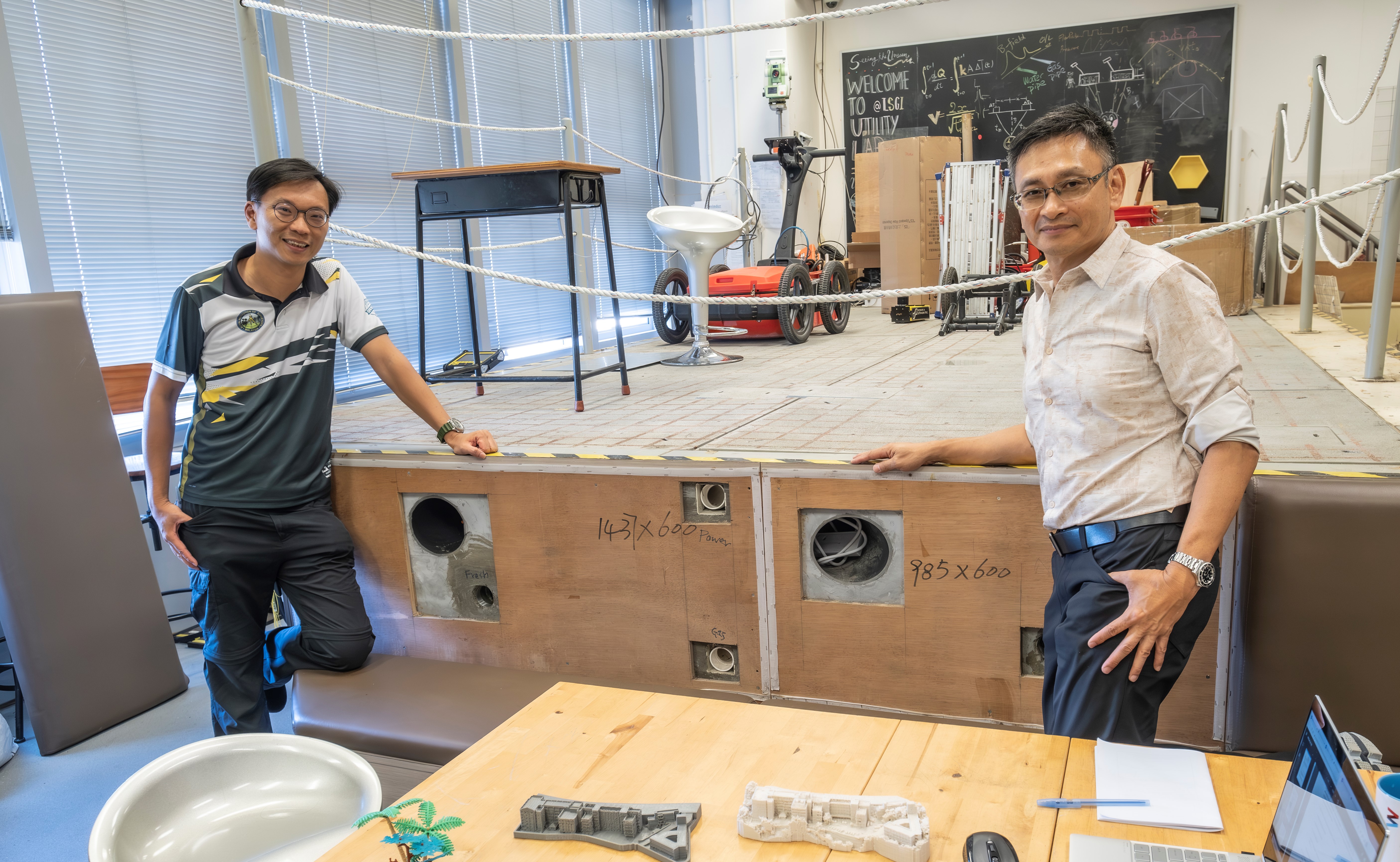

In addition to the preventive maintenance for external walls, another construction currently underway by the CSFO at PolyU is the installation of a new underground water pipeline system. The LSGI team is also involved in this project, as the surveying technology and specification consultants.

Taking environmental factors into consideration, PolyU aims to convert the current freshwater to seawater for flushing and set up a new water pipeline system underground, with seawater being supplied to the campus through the water supply points of the Water Supplies Department. Due to the heavy traffic on Yuk Choi Road, as well as the complexity of the existing underground pipeline and cable network, PolyU employed electromagnetic sensors for underground surveying. Geographic Information System (GIS) and Building Information Modeling (BIM) were also utilized to create 3D images.

These digital 3D images provide elaborate information about the existing underground utilities, including their locations, directions, materials, and even approximate depths of the facilities. Compared to traditional construction drawings created using computer-aided design (CAD) software, these 3D images offer a wealth of additional information that facilitates project planning, budget allocation, and work efficiency, while chances of errors during the construction process can also be reduced.

"In the past, we could only dig up the road surface to survey as we go, and workers couldn't accurately assess the conditions of the underground utilities and the depths of the facilities, in which case the risk of damaging water pipes and cables is unavoidable," Wallace explained. Even bidders can provide more accurate quotations, with this data being incorporated into the tender documents.

Utilizing the GIS and BIM, Wallace, his PhD student Samuel Yu and LSGI's Scientific Officer Ms. Serein Han successfully produced 3D images for PolyU’s campus to find out the location of the existing underground pipeline and cable network.

From the image, it is evident that digital 3D images can clearly reveal the intricate underground pipeline network that spans the entire campus, helping to improve planning and construction efficiency, reducing the chances of errors in the project, and enabling PolyU to direct seawater into the campus’ flushing system.

Information including the positions, directions, materials, and even approximate depths of underground utilities and cables, is all clearly visible in the image.

Technology, Tender Specifications, and Accreditation are all Indispensable

In spite of the innovation in the surveying technology, which can enhance efficiency and safety, the lack of a unified measurement standard can lead to inconsistent results in the industry, and the varying ways of performing the tests can also result in inconsistent inspection quality.

In addition to Hong Kong Concrete Institute’s invitation to revise the current inspection specifications standard for external walls used in the Hong Kong industry (HKCI TM 1: Issue 2: 2022)2, Wallace, at the request of the Government, and with the support of the Innovation and Technology Fund, is also leading the development of industry standards for non-destructive testing, surveying, imaging and diagnosis for underground utilities (NDTSID-UU)3, which comprises of establishing a standardized framework and qualifications framework for the surveying equipment, calibration, and processes used.

In this regard, he has been collaborating with the Hong Kong Accreditation Service, other relevant government engineering departments and consulting firms, in the hope that the industry will adopt this unified surveying standard in tender documents and promote the accreditation of 4M1E based on the specifications of the Hong Kong Accreditation Service4.

"These standards have been widely consulted within the industry between 2018 and 2021 through 9 meetings with over 50 senior leaders from the Government and the industry. These standards have been developed based on practicality and the technology available at the time, so they are objective, representative and feasible to be included in the Government’s accreditation framework. Some of these standards have been adopted in related engineering/surveying projects, not only in Hong Kong but other parts of the world, such as Singapore," said Wallace.

Currently, these standards and specifications have been incorporated into two engineering tender documents at PolyU, allowing the university to identify engineering companies with relevant qualifications in advance. Certified bidding companies have also gained a competitive advantage as a result, which will ultimately contribute to improving the efficiency of the industry's development.

Wallace believes that if PolyU regards these standards and requirements as guidelines for tendering, the university can serve as a model for the industry and inspire others to follow suit. "These valuable experiences in verification and application using technology, formulation of tender documents, management of construction work, and my interaction with the industry regarding standards and certification can all be part of my teaching materials at PolyU, conducive to both education and research, passing on knowledge to the next generation."

A Tender Process and Successful Model Built upon Empirical Data and Accredited Laboratories

Wallace believes that the formulation of the tender process and its details are crucial to the successful implementation of construction and engineering projects.

Currently, many surveying and measurement works for external walls and underground utilities in the industry are outsourced as lump sum contracts, where a single lump sum is paid to the contractor, who then allocates the expenses for different parts of the project. In order to increase profits, some contractors reduce the costs of surveying, resulting in a decline in the quality of the construction work.

Furthermore, awarding both the inspection and the works to the same engineering company may pose difficulties for proper supervision. Take the preventive maintenance project of external walls as an example, as Wallace explained, "The condition of the external walls is a concern, and whether the contractor would report all the locations of delamination as detected during the inspection is another issue because the extent of delamination affects the project expenses directly and the contractor's profit indirectly."

In this regard, the mechanism of measurement contract is adopted at PolyU, where tentative quantities of works are established, on which the estimated amount for the repair works is calculated, ensuring fairness in the tendering process. Additionally, all the inspections are arranged internally by PolyU. "We understand that the industry may not have the technical expertise for the inspection, so including it in the tender documents would only discourage contractors or lead to unreasonably high bids," Wallace continues, "PolyU itself is a research institute, and the CFSO has a large pool of talents to handle this part."

However, he believes that these procedures will be taken up by the industry in the near future. "It is our responsibility to transfer knowledge and technology, and ensuring its sustainability in the commercial world is an even more important concern for us."

Wallace (left) is demonstrating an underground pipe model and explaining some surveying principles. These models are his everyday teaching aids.

PolyU received the Bronze Award at the 22nd Hong Kong Occupational Safety and Health Award for the “Preventive Maintenance Program Against Falling Tiles of Building Façade”.

1 https://www.itc.gov.hk/en/quality/hkas/doc/SupplementaryCriteria/HOKLAS_SC-19.pdf

2 http://www.hongkongci.org/wp-content/uploads/2022/08/HKCI-TM1-2022.pdf

3 https://www.polyu.edu.hk/lsgi/uusspec/en/publications/

4 https://www.itc.gov.hk/en/quality/hkas/doc/SupplementaryCriteria/HOKLAS_SC-55.pdf