World’s First Antiviral 3D Printing Material

Effortlessly reducing surface transmission risk of COVID-19

In recent months, as Hong Kong has faced its worst wave of outbreak of COVID-19 so far, the issue of community hygiene catches public attention again as the virus can remain active on plastic and stainless steel up to 72 hours[1]. “This surface is sanitised every hour,” reads a notice next to the lift call button. With gratitude to the caretakers who burn themselves out by disinfecting high-touch surfaces in public areas repeatedly for our safety, one can’t help thinking if manual cleaning and sterilisation are the ultimate answer to stop surface transmission of the virus.

Pitfalls of manual disinfections and antimicrobial coatings

Not only are they labour-intensive, but also never frequent enough. A lift button in a busy office tower could be touched by hundreds of users within the hour between manual disinfections. The same applies to door handles in public places and handrails on public transport. Spray-based antimicrobial coatings work better by staying effective for up to months. But with daily wear and tear alongside additional manual cleaning with disinfectants like alcohol and bleach, the coatings might as well have detached from the surfaces without the users knowing.

“That’s why it’s desirable to develop a product that keeps performing its antimicrobial action every moment throughout its whole lifecycle, despite daily wear and tear and repeated cleaning,” said Dr Chris LO Kwan-yu, Associate Professor, Institute of Textiles and Clothing (ITC), who led an interdisciplinary research team to develop the world’s first antiviral 3D printing material, proven to wipe out up to 99.9% of common bacteria on its surface within 20 minutes, including those found on doorknobs and toilets. As for COVID-19, the material is proven to kill 99.2% of it and its variants within 20 minutes. “Even without regular disinfections, the surface would always stay virus-free, greatly reducing the risk of surface transmission. The material stays highly effective even if the material surface is damaged.” he added.

Kills all mutant variants

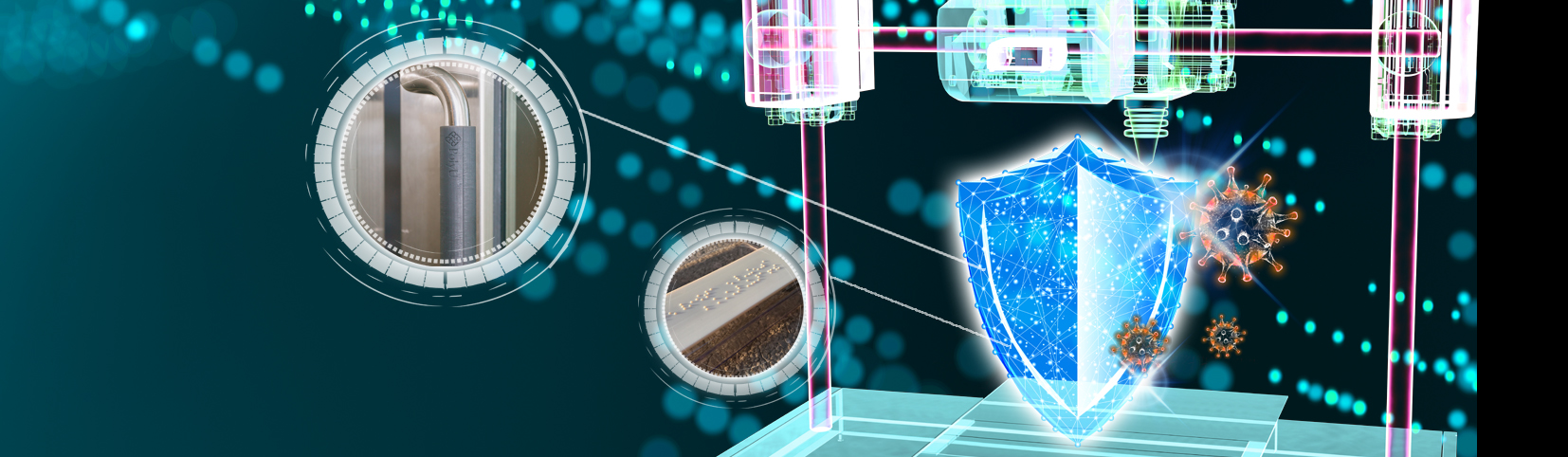

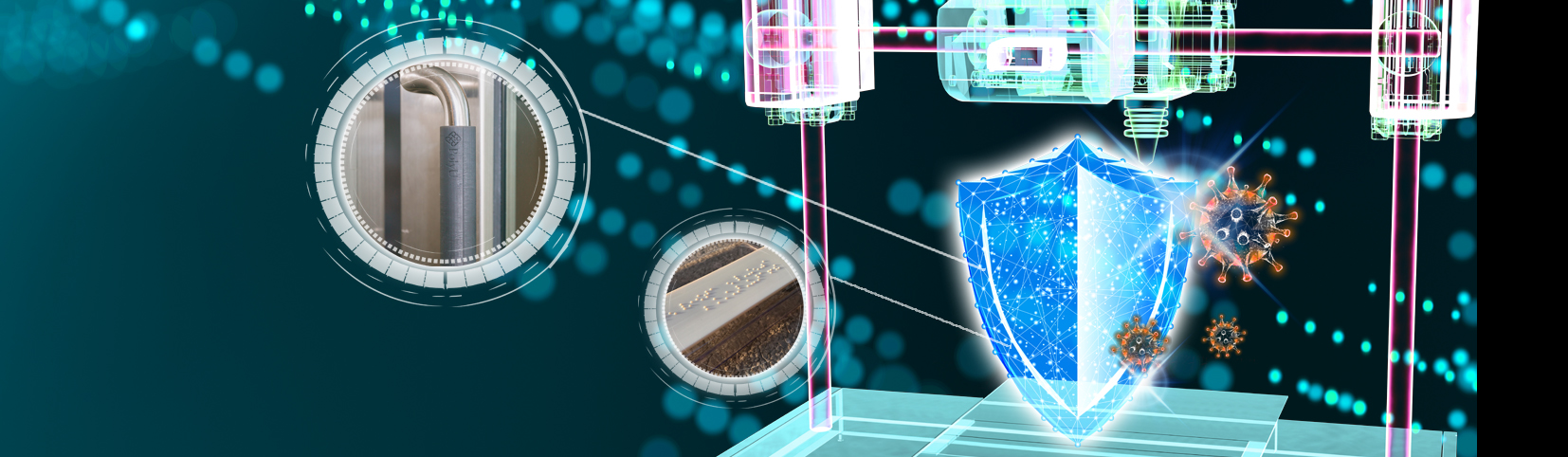

The material is a resin with antiviral agents embedded and distributed throughout its structure, instead of a coating just sitting on the surface. Scratching the surface and daily cleaning with disinfectants won’t compromise its performance. According to Prof. Kan Chi-wai, a member of the research team and Professor of ITC, “the antiviral agents work by physically puncturing the pathogens’ cell membranes and destroying their structures with positively charged cations. That means they kill all kinds of COVID-19 viruses including any mutant variants.” The research team spent over 6 months to achieve an optimal formula of the material, trying to maximise the antimicrobial action without undermining the physical strength and properties of the resin.

With the support from PolyU’s University Research Facility in 3D Printing (U3DP), the team put the antiviral 3D printing material on field trials in conjunction with the Home Affairs Department, the Hong Kong Wetland Park and an environmental organisation. High-touch surfaces such as recycling bin handles, covers for toilet doorknobs, lift buttons and Braille signs made with the material were found to be free of viruses and bacteria after one year of use without daily cleaning. The material would still kill 85% of viruses and bacteria within 10 minutes after three years of simulated use. “The material can be 3D-printed into different forms for different needs. Because of its flexibility, it can be applied to public facilities extensively,” Dr Lo remarked.

Startup with lofty mission

To commercialise their revolutionary invention, Dr Lo and Prof. Kan co-founded a startup, Immune Materials Limited (IML), in May 2021. “Our mission is to protect people with innovative long-lasting antiviral solutions. We want to contribute to the re-industrialisation of Hong Kong by developing a local brand with a local supply chain – from inception and R&D, to manufacturing and marketing. In a long run, we want our brand to be a seal of confidence, a trusted sign immediately recognised by a global audience for its remarkable antimicrobial action,” explained Dr Lo.

The long-lasting and non-stop antimicrobial action of the material also makes it perfect for use in environments with high risk of pathogen transmission such as hospitals. He said, “So far, three private hospitals have placed initial orders to use our material for high-touch surfaces. One public hospital is working with the team to develop more antiviral applications in clinical areas.” Currently, the researchers are looking into the possibility of using it in other public facilities, including school campuses (e.g. Tung Wah College), hotels (e.g. Hotel ICON) and buildings managed by property management companies.

As a proud participant of PolyU Lean Launchpad Programme – Health Track, IML was assigned an advisor who has extensive experience in the biomedical industry and profound knowledge in patent applications and management in China. Dr Lo considered him a great asset for the enterprise in preparation for venturing into the mainland Chinese market. IML was also accepted in the Incubation Programme of the Hong Kong Science and Technology Parks.