Belt and Road Advanced Professionals graduated from University-Industry Collaborated Programme of PolyU-XJTU Silk Road International School of Engineering

Senior professionals from 12 countries/regions have benefited from the Belt and Road Advanced Professional Development Programme in Power and Energy run by The Silk Road International School of Engineering (SRISE) for the second consecutive year. The graduation ceremony for the 25 participants staged today on The Hong Kong Polytechnic University (PolyU) campus was officiated by Mr Matthew CHEUNG Kin-chung, Chief Secretary for Administration of the Hong Kong Special Administrative Region.

The three-year Programme run by SRISE — a joint establishment of PolyU and Xi'an Jiaotong University (XJTU) — in partnership with State Grid Corporation of China (State Grid) and The Hongkong Electric Company, Limited (HK Electric) is the first cross-regional and multi-cultural project of its kind in Chinese Mainland and Hong Kong, and the first university-industry collaboration project of SRISE.

Over the past two weeks, the 25 professionals in power and energy sector participated in field-trip studies and exchanges in Xi'an, Jinan and Hong Kong. Newly joining the Programme this year were participants from four nations, namely Brazil, Myanmar, Nigeria and Tanzania. The participants include senior executives from enterprises or government agencies, as well as veteran academics and researchers.

Other officiating guests at the graduation ceremony today were: Dr Lawrence LI Kwok-chang, Deputy Council Chairman of PolyU; Professor XI Guang, Vice President, Xi'an Jiaotong University; Mr SU Qingmin, Director, Management Centre of Education Affairs, State Grid of China Technology College; and Mr WAN Chi-tin, Managing Director of HK Electric. Mr LIU Zhiming, Deputy Inspector, Department of Educational, Scientific and Technological Affairs, Liaison Office of the Central People's Government in the HKSAR,as well as a number of Consulate Generals or representatives from the Belt and Road region, including Malaysia, Russia and Tanzania, were also present.

Addressing the ceremony, Mr Matthew CHEUNG Kin-chung, Chief Secretary for Administration of the HKSAR, said, "Embedded with 'five areas of connectivity', namely policy co-ordination, financial integration, unimpeded trade, facilities connectivity and people-to-people bonds, the Belt and Road Initiative provides new impetus not only to the global economy, but also sustainable development. I believe that as part of PolyU's Belt and Road Strategic Platform, this Programme echoes well with one of the key focuses of the Initiative on the establishment of energy partnerships. Hong Kong has a unique role to play in this vision. The strengths of Hong Kong's energy sector in system operation, manpower development and project financing are most pertinent."

Dr Lawrence LI Kwok-chang, Deputy Council Chairman of PolyU, said, "The Belt and Road Initiative is a powerful engine that not only provides numerous opportunities of development, but also creates a huge demand for professional talents. Obviously, engineers are highly sought after. As PolyU excels in the engineering discipline, we are keen to capitalize on our strengths to support the training of engineers from Chinese Mainland as well as the Belt and Road countries……We need partners in order to do a good job. We are therefore very honoured to have partners from the higher education sector and industry in both Chinese Mainland and Hong Kong to run this professional development programme."

Professor XI Guang, Vice President, Xi'an Jiaotong University, said, "Through this Programme, we hope to strengthen the cooperation in technology spectrum among Belt and Road countries/regions, and to introduce a new model for university-enterprise and university-community collaboration. We also aim to implement the work plans under the University Alliance of the Silk Road framework, so as to contribute towards nurturing elite talents with global vision."

Mr SU Qingmin, Director, Management Centre of Education Affairs, State Grid of China Technology College, said, "The first workshop run jointly by XJTU, PolyU, HK Electric and State Grid Technology College in April last year has received very good feedback. This year, with great enthusiasm, the four partners have meticulously planned a series of technological lectures, field trips and cultural exchange events in Xi'an, Jinan and Hong Kong. State Grid Technology College has been responsible for the 4-day activities in Jinan. We are very proud to have such opportunity to share with backbone members and elites from the industry, universities and government sector."

Mr WAN Chi-tin, Managing Director of HK Electric said the company has been providing safe and reliable power supply for Hong Kong with a world-class reliability record of over 99.999% for 22 years consecutively. "As Hong Kong is taking steps to become a Smart City, we are keen to enable our customers to use energy smartly. That is why we are investing in infrastructure that promotes the widespread adoption of information and communication technologies. And in line with the Government's Smart City initiatives, we plan to roll out smart meters for most of our customers over the next 7 years. Through this workshop, we are happy to share with our visitors our unique experiences, " he said.

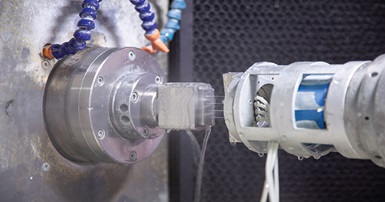

This year's Programme focused on "Ultra High Voltage, Smart Grid and Electricity Infrastructure for Resilient City". The participants had field-trip study at the State Key Laboratory of Electrical Insulation and Power Equipment in Xi'an, as well as various practical training facilities of State Grid in Jinan. In Hong Kong, they visited the System Control Centre and Lamma Power Station of HK Electric, and have exchanges with PolyU academia on Artificial Intelligence for Electricity Supply. The 11-day Programme enabled them to learn about cutting-edge technologies, modern management system and advanced design of the cities' special power supply facilities, and to gain practical knowledge and experiences from veteran academics and professionals from PolyU, XJTU, State Grid and HK Electric.

[From PolyU Media Release]

Related News Articles:

張建宗:港成「一帶一路」專才平台 [香港商報 (Hong Kong Commercial Daily)]