Antimicrobial plastic with lasting action reduces surface transmission risk of diseases, especially among those most vulnerable

Some novice entrepreneurs are willing to compromise a few principles as long as they can raise fund while some are very specific about their stance and who their investors are. Prof. Kan Chi-wai and Dr Chris Lo Kwan-yu of School of Fashion and Textile (SFT) co-founded Immune Materials Ltd (IML), a pioneer in antiviral and antibacterial plastic products using 3D-printing and other traditional means of production. They strongly believe in corporate social responsibility and the importance of fostering an inclusive society. “Good technology should not only help the majority, but also the minority whose voice is never heard, whose interest is often side-lined or even ignored. This is our core value. We are only interested in working with investors who share the same views with us,” says Dr Lo.

Lasting and non-stop action

It’s been almost three years since the pandemic started. Most of us have developed a habit of not touching any surface in public places with bare hands because COVID-19 virus can remain active on objects and surfaces up to 72 hours. We can hire janitors to disinfect all surfaces. But no matter how frequently done, it takes just one carrier to contaminate a surface. And someone could be infected if it’s not sterilised again right away. There are antimicrobial coatings that keep a surface germ-free for months, but their action becomes dubious as they can be easily scratched off or damaged by disinfectants like alcohol and bleach.

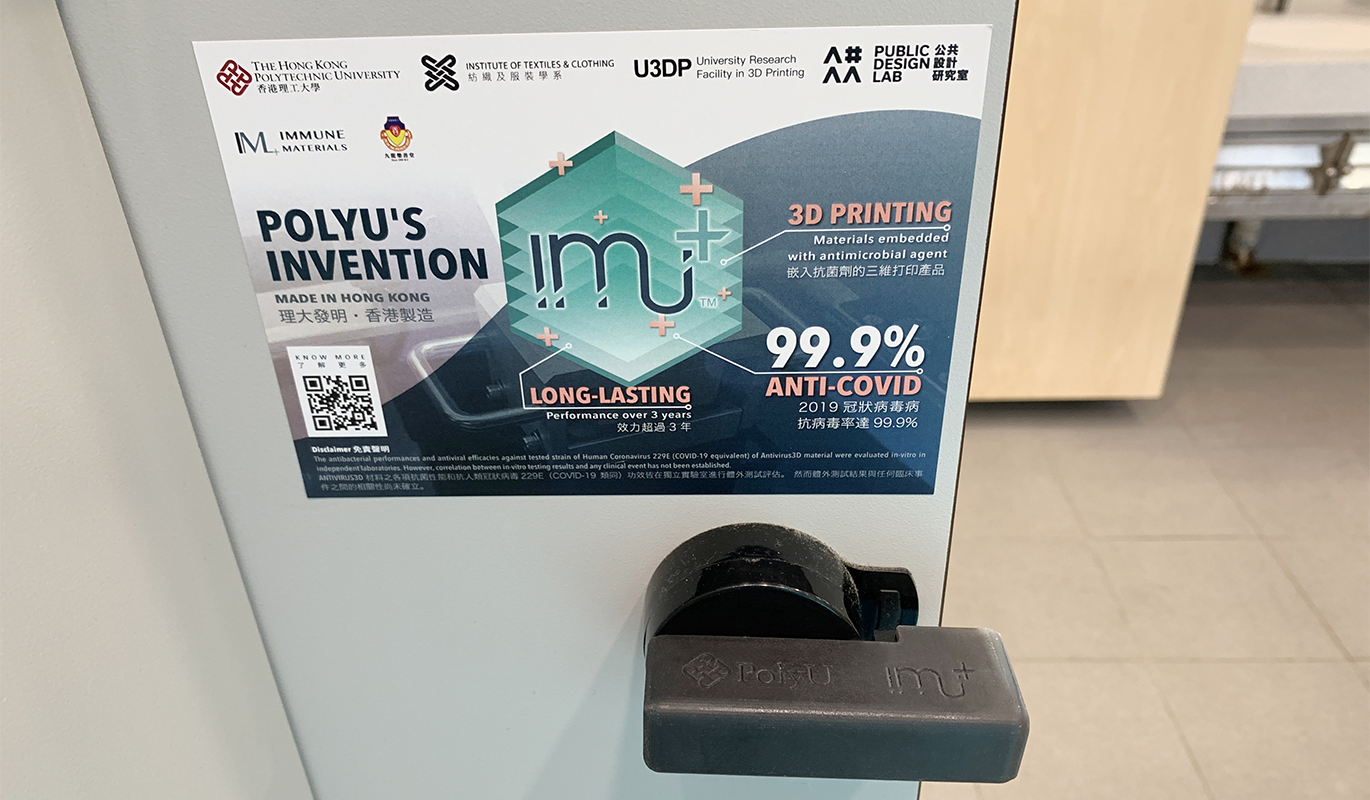

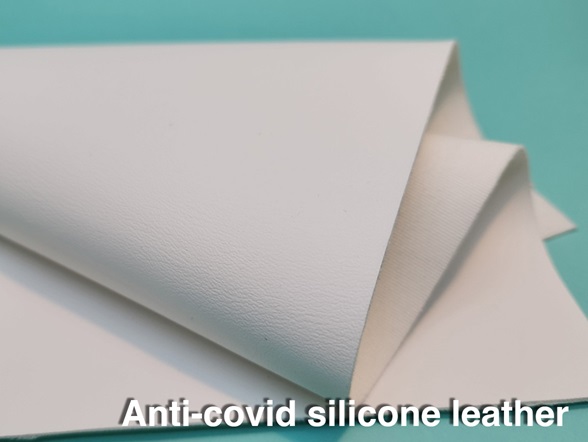

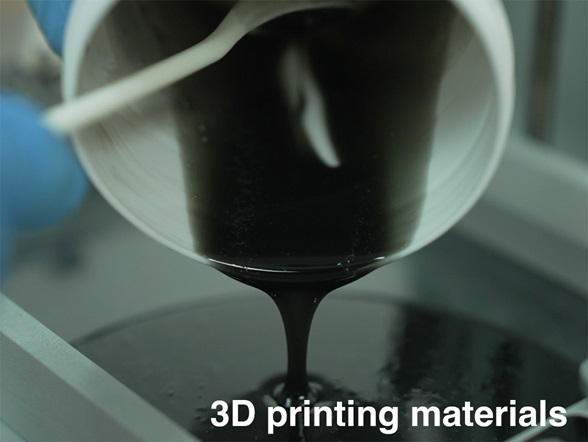

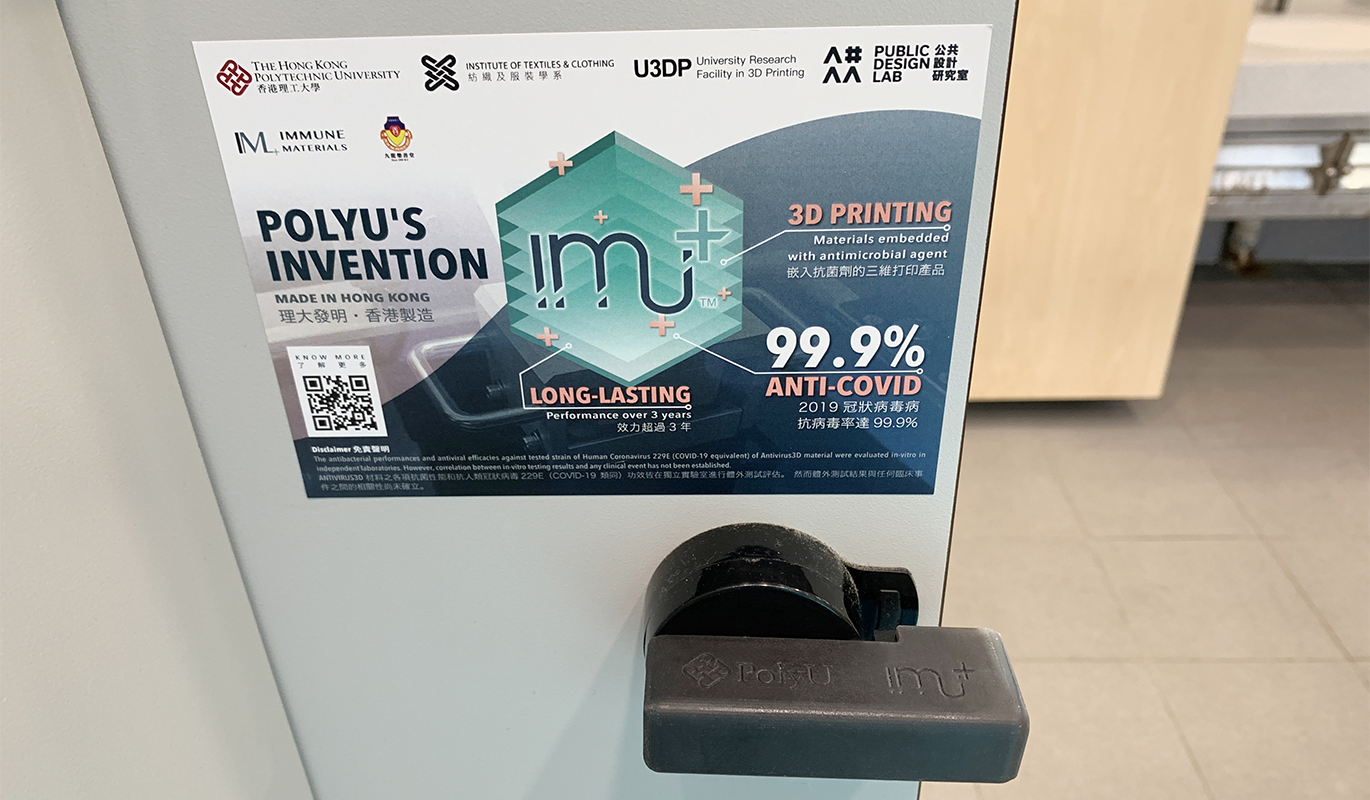

The truly long-term solution should keep performing its antimicrobial action every moment throughout its whole lifecycle, despite daily wear and tear and repeated cleaning. And IMU+® by IML is the answer. Proven to wipe out up to 99.9% of common bacteria and 99.2% of COVID-19 variants within 20 minutes, IMU+® products and materials developed by IML are guaranteed to stay effective for up to three years even if their surfaces are damaged. Antimicrobial agents are embedded in the resin and distributed throughout its structure so that scratching the surface and daily cleaning with disinfectants won’t compromise its performance. According to Prof. Kan, “the antimicrobial agents work by physically puncturing the pathogens’ cell membranes and destroying their structures with positively charged cations.” Not only can IMU+® plastic be 3D-printed, but also incorporated in plastic pellets for conventional production methods such as injection moulding.

Caring for the less-privilege

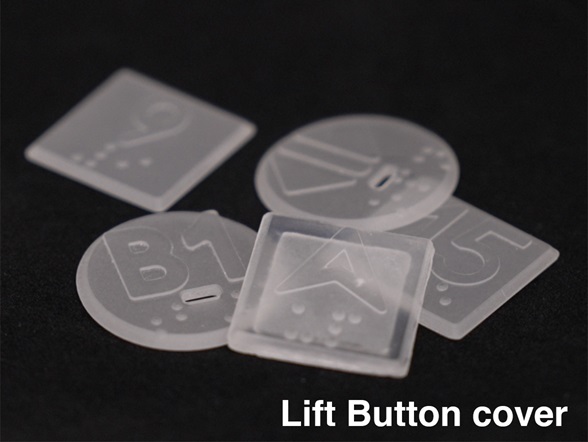

IML was founded in 2021 and was accepted into the incubation programme at Hong Kong Science and Technology Parks in the same year. In January 2022, IML announced their IMU+® technology for the first time and attracted much attraction amid the fifth wave of COVID outbreak in Hong Kong. As IMU+® plastic can be 3D-printed flexibly into different forms, such as handles, door knob covers, and lift buttons, it was soon applied to public facilities extensively, especially in environments with high risk of pathogen transmission such as quarantine centres, hospitals, schools and hotels.