Valorization of Organic Wastes into Biochemicals

Global warming and depletion of fossil fuel resources have urged our research to enhance the utilization of renewable resources for biofuels and biochemical production. Green bio-based technologies (e.g., biorefinery) have also created growing opportunities to support agricultural industries. Agro-industrial biomass is a sustainable source of biorefinery feedstock for bioconversion into a range of value-added products. Modern biorefinery aims to utilize all the building block chemicals (cellulose, hemicellulose, and lignin) while lignocellulosic biomass is recalcitrant to biodegradation and enzymatic hydrolysis.

Therefore, our research aims to isolate and identify the xylose-utilizing bacterial strains for converting the biomass “whole sugars” into useful industrial products. As a part, the recent research project is centred on 2,3-butanediol (2,3-BDO) production. Based on the diverse chemical nature of the feedstock, strategic design of the bioprocesses, accompanied with high-throughput omics studies and sustainability analysis are demonstrated for determining the magnitude of green production of biofuels and value-added chemicals in next generation biorefinery.

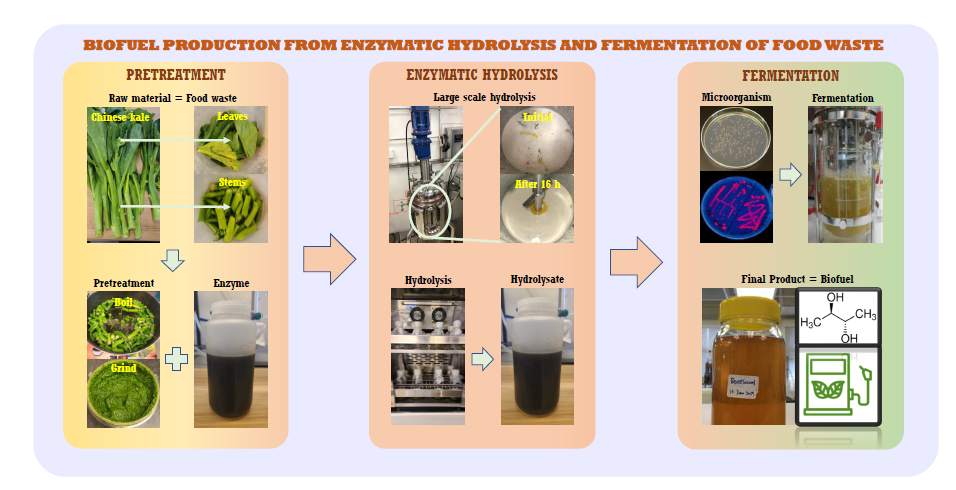

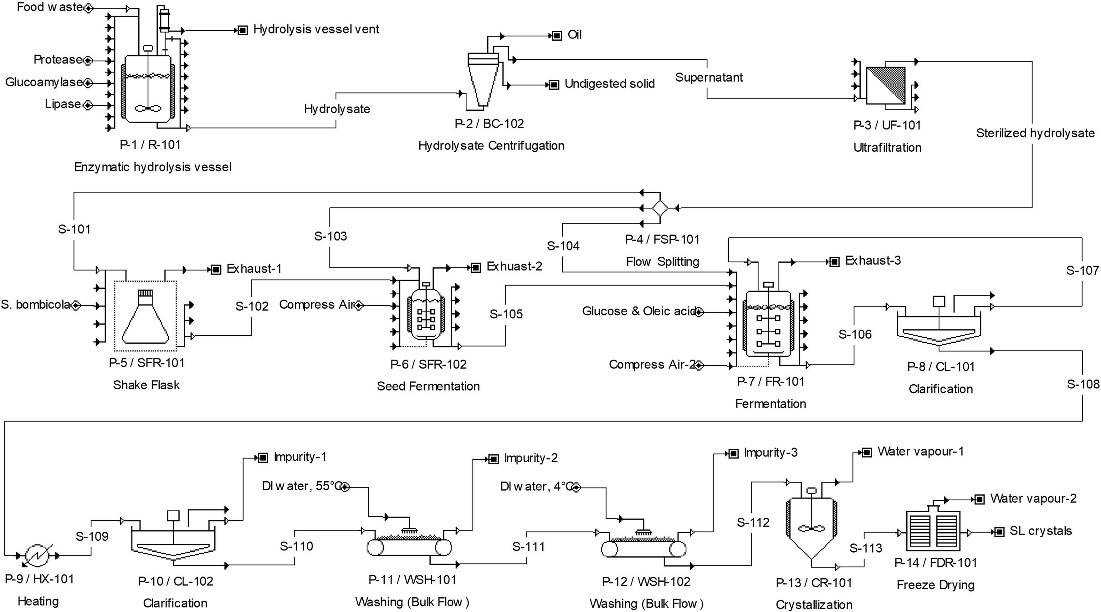

Conversion of Food Waste to Biofuels

According to Hong Kong Environmental Protection Department (EPD), more than 3000 tons of food waste is generated every day in Hong Kong in 2019. This accumulating food waste is disposed by dumping into the landfill, which creates another problem. Food waste occupies majority portion of landfill in the limited space of Hong Kong and generates methane in the landfill, which is a harmful greenhouse gas. Hence, a new method to treat food waste is necessary. In our laboratory, we process food waste and convert it into valuable biofuel by enzymatic hydrolysis and fermentation. Food waste contains abundant carbohydrates, proteins, and lipids which can be transformed into hydrolysate containing rich glucose, amino acids, and fatty acids by enzymatic hydrolysis. Subsequently, the hydrolysate is used in a fermentation to produce valuable biofuels or other chemical commodities. Our laboratory promotes green biorefinery and circular economy approach using food waste to produce valuable and environmentally friendly products.

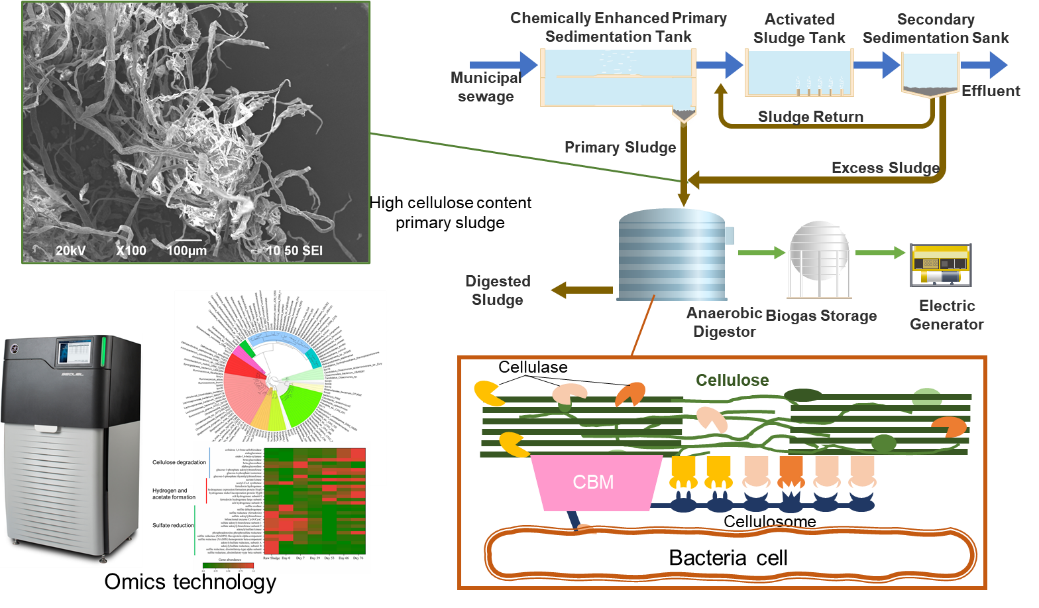

Anaerobic Digestion of High Lignocellulose Sewage Sludge

Carbon neutrality is an environmental-friendly target toward our sustainable future. Resources mining from municipal wastewater has also become an emerging goal under a global perspective. Energy-saving operation has been practiced in wastewater treatment plants (WWTPs) through careful adjustments of aeration energy supply and biogas recovery from the anaerobic digestion (AD) used for treating biosolids. Chemically enhanced primary treatment (CEPT) is a unique WWTP approach progressively adopted by mega-cities to improve energy- and land-efficiencies. The roles of enriched cellulosome-forming bacteria, abundances of cellulosome-related genes, their associations with syntrophs and methanogens, and feedback to characteristics of substrate still remain unclear. Our research aims to assess the prospects of cellulose carbon transformation and cellulolysis metabolism to methane from AD. We employ techniques such as, 16S rRNA gene and meta-genomics analyses, to elucidate the interspecies interactions, identify the cellulosome-related genes, understand cellulosic degradation pathways, and clarify the carbon flow. The findings provide essential biological insights to facilitate the stability of ADs for bioconversion of cellulose-rich substrates, i.e., food wastes, lignocellulosic biomass, and/or non-recyclable paper, which facilitate the paradigm shift of WWTPs from an energy-deficit to an energy-sustainable industry.

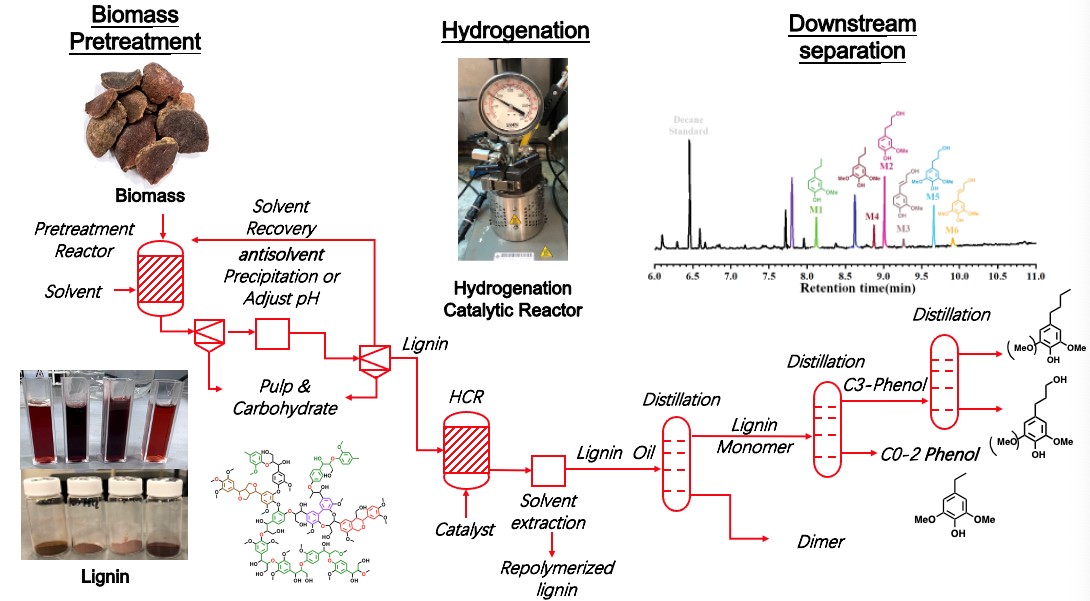

Conversion of Biomass to High-value chemicals

Solid waste is an emerging environmental problem associated with urbanization and is particularly serious in highly populated cities like Hong Kong. Developing biorefinery technologies to harvest renewable fuels and chemicals is a promising strategy to response the society’s awareness on sustainable development. Among the biorefinery techniques, pre-treatment is the most critical process to fractionate the plant cell wall and hence to harvest the important building block chemicals for further processing. The conventional pre-treatment approaches are carried out at elevated temperature with various chemicals to remove hemicellulose and lignin. However, the harsh reaction environment can result in lignin degradation and condensation, which can seriously reduce the yield of valuable lignin and fermentation products. The high-temperature process also requires high-profile digester and can result in high concentration of harmful by-products. Mild pre-treatment techniques are needed to facilitate the biorefinery economy. We are attempting to develop a new hybrid acid based low pressure organic solvent (using 1,4-butandiol) pre-treatment process to decompose biomass into basic monomers, i.e., 6- and 5-C sugars and monolignols.

Lignin valorization toward value-added chemicals

Until very recently, lignin was considered a waste as the material potential of lignin remains largely unused with 98% of lignin being burned. But times are changing, and tremendous amount of research has been conducted in order to unlock the full potential of lignin, addressing various aspects of lignin reactivity, chemistry and utilization with the hope to make breakthroughs in the field of lignin valorisation. Our research is aims to untap the lignin’s potential by converting lignin into value added products such as membranes, foams and other composite material that can be used for water and wastewater treatment and various other high-performance applications.

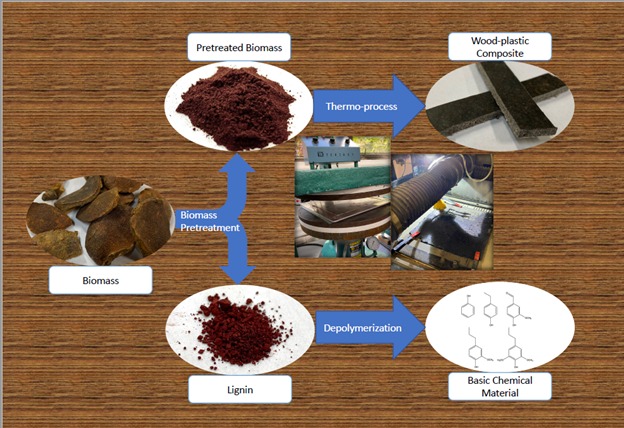

From Biomass to Bio composites

Biomass is an important solid waste found in Hong Kong, 170 ton of woody biomass was formed every day. How to effectively use these waste materials that should be transported to landfills is a very important research topic in recent years. Lignin was found to be an important polymer that can be used as the source to produce biofuel, which is a renewable energy source. The pre-treatment method to extract lignin is a huge factor to affect the percentage of lignin extract and the quality of lignin. In our group, we are developing the method to have a high lignin removal rate and high lignin quality which extract from the biomass and undergo depolymerization to form biofuels. After the extraction of lignin, the residues can still become valuable products through different methods. Wood-plastic composite is a common product that we found in the daily life that produced by the woody biomass, in this case, we are developing the method to produce wood-plastic composite by using the residues of pre-treatment as the source of biomass. As a result, all the lignin and residues in the biomass can be used to turn into biofuels and composite products

Techno-economic analysis (TEA)

TEA can be used for studying new technologies or optimizing existing ones. Ideally, a techno-economic model represents the best current understanding of the system being modeled. The following are examples of what we do at GEPL in regards to TEA.

Evaluating economic feasibility: TEA can be used to anticipate whether a process will be sufficiently profitable under a certain set of assumptions. It can thereby help companies to avoid pursuing dead-ends.

Guiding research and development: When combined with sensitivity analyses like Tornado Diagrams, TEA can be used to identify research and development (R&D) targets with the greatest potential to improve profitability. In this way, it can help companies bring their technologies to market more efficiently.

Quantifying uncertainty and risk: Sensitivity analyses like Tornado Diagrams and Monte Carlo analysis can be used to quantify economic uncertainty in the model results. They can also be used to identify which variables are the source of the most uncertainty.