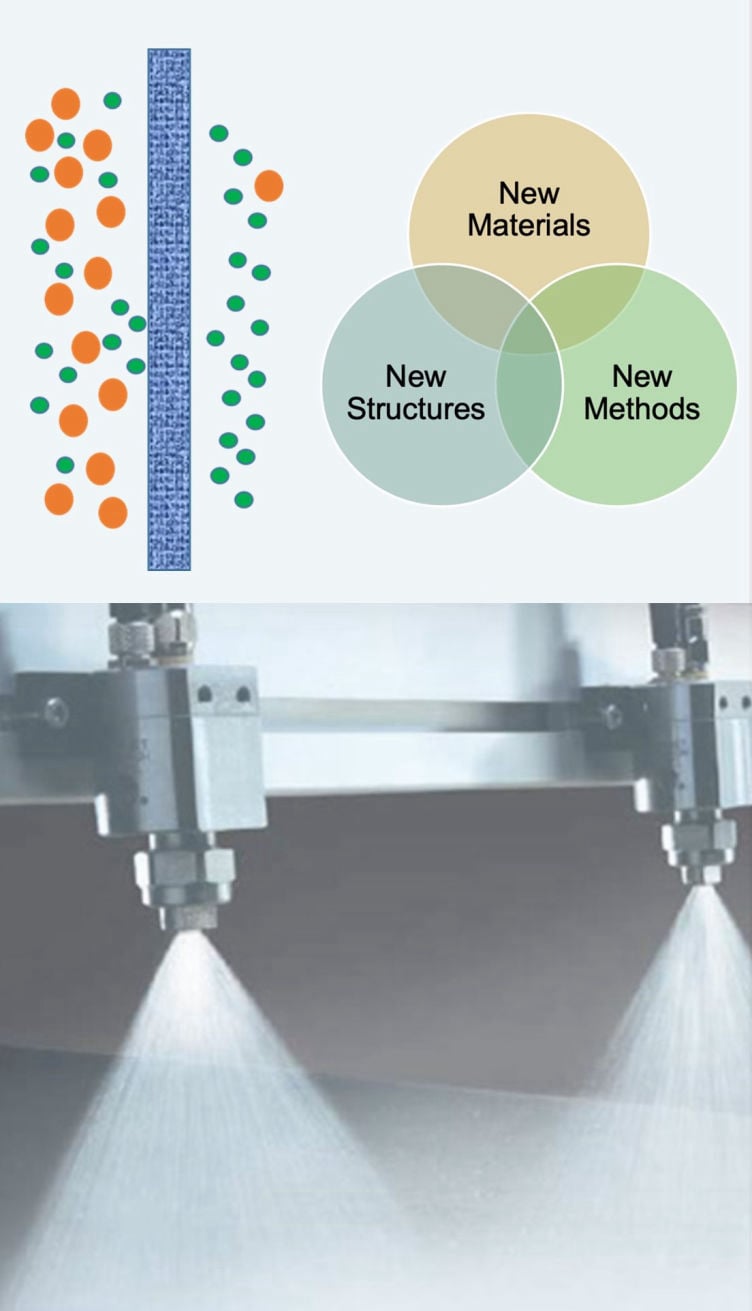

Reinvent membranes at the nexus of novel material, structural redesign, and fabrication approach

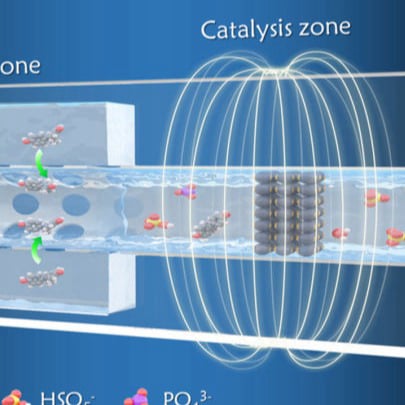

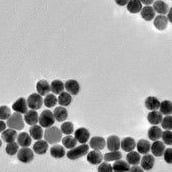

Membrane separation is one key process in advanced water treatment due to various technical advantages such as small footprint, high separation efficiency, and relatively affordable costs. However, their more widespread applications are hindered by several technical challenges such as a trade-off between permeability and selectivity, fouling, and low chlorine resistance, among others. These challenges can be effectively addressed by developing a new generation of membranes, enabled by the use of novel membrane materials, the redesign of membrane structure, and the engineering of advanced fabrication approaches. We are actively exploring the assembly of emerging membrane building blocks (such as carbon and catalytic nanomaterials, polyelectrolytes, covalent organic frameworks) into novel membrane structures (mixed matrix or layer-by-layer assembly), assisted by new scalable aerosol-assisted printing approaches. Our current research has been focused on the development of nanocomposite ultrafiltration (UF), polyelectrolyte multilayer (PEM) and covalent organic framework (COF) nanofiltration (NF) membranes.

Ongoing projects:

1. Catalytically Reconstructed Covalent Organic Framework Membranes for Water Purification (Funded by Hong Kong RGC GRF, 2025-2027)

2.Polyelectrolyte Nanofiltration Membranes via Aerosol-assisted Printing: Establishing Fabrication-Structure-Performance Relationships towards Scalable Manufacturing and Applications in Advanced Water and Wastewater Treatment (Funded by Hong Kong RGC GRF, 2023-2025)

3. Development and Application of Nanocomposite Membranes via 3D Printing for Water Treatment (Funded by Shenzhen STIC, 2022-2024)

Completed projects:

1. Advanced Nanocomposite Membranes Synthesized by An Aerosol-assisted Fabrication Approach for Water and Wastewater Treatment (Funded by Hong Kong RGC ECS, 2020-2023)

2. Carbon Nanomaterials-Polysulfone Nanocomposite Ultrafiltration Membranes: Revealing Synthesis-Structure-Performance Relationships (Funded by NSFC, 2020-2022)