Fundamental Asphalt Research

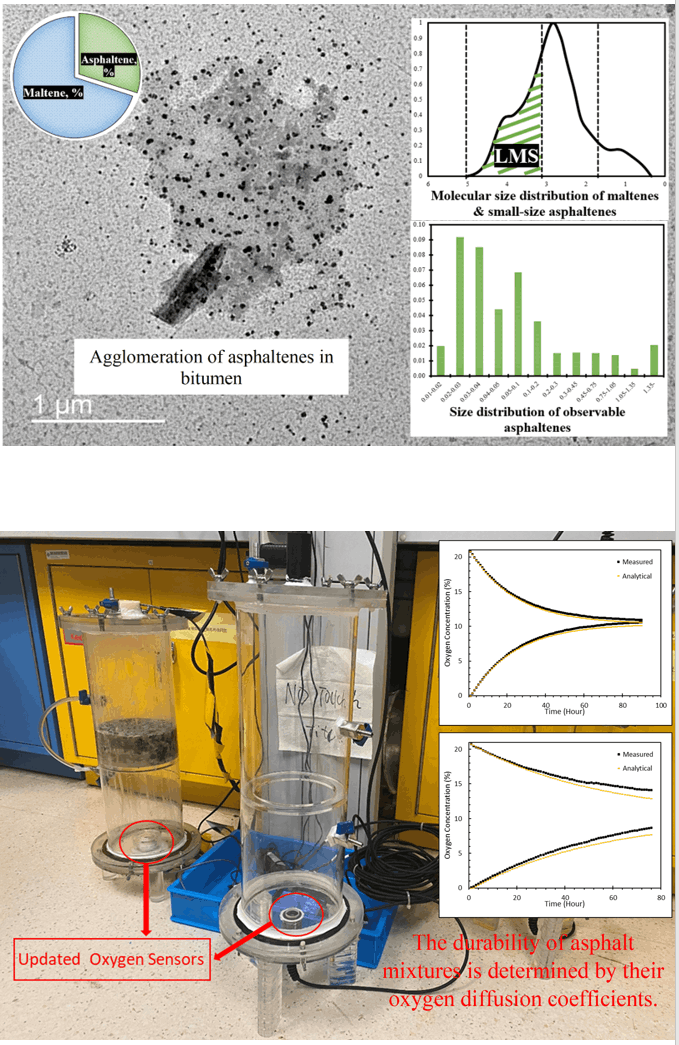

Dr. J. Claine Petersen, a prominent asphalt scientist at Western Research Institute, once stated that “The study of these (asphalt) molecular interactions at the nanoscale level, and their effect on physical and chemical properties measured at the macro level, is what is meant by physicochemical characterization. This is asphalt’s “black box” in which its most guarded secrets are kept.” Over the years, our group has been trying to disclose image this “black box” by revealing the physicochemical origins of asphalt property variations. We invented new methods to assist the characterization of asphalt binders at the molecular level and nanoscale. Using such methods, we are the first research group that discovered the interesting asphaltene microstructures in asphalt binders and how the microstructures change with binder aging. We found that nearly all the engineering properties of asphalt binders (stiffness, fatigue, relaxation) can be well explained through the nanoscale microstructures and their interactions with binders’ liquid phase. Such findings can help us identify and develop more durable asphalt binders. We also developed methods to evaluate and improve the durability of asphalt mixtures from the perspective of anti-aging.

Urban Waste Management

Our team studies urban waste management through an integrated, system-oriented approach including society and industry participation, materials, construction, and logistics. In asphalt pavements and road bases, we investigated high-percentage incorporation of reclaimed asphalt pavement (RAP), reclaimed asphalt shingles (RAS), and industrial by-products (e.g., steel slag, fly ash) without downgrading performance, linking microstructural and rheological characterization to durability metrics (aging, moisture damage, fatigue, rutting) and field-relevant QA/QC protocols. Beyond pavements, we also developed technosols (artificial soils) that valorize construction and demolition waste with stabilizers to deliver both geotechnical function and environmental co-benefits for urban greening. On the construction side, process optimization and sensor-informed quality control reduce waste generation and rework, while lifecycle assessment (LCA/LCC) quantifies carbon and cost impacts to guide specification and procurement. At the system level, we used industrial ecology reverse logistics to optimize waste supply and enhance circularity. On the domestic waste side, we organized household participatory programs and turned household waste to agricultural resources. Collectively, these contributions provide validated methods, design indicators, and implementation playbooks that enable relevant stakeholders to effectively turn waste into resources and reduce landfill burdens.

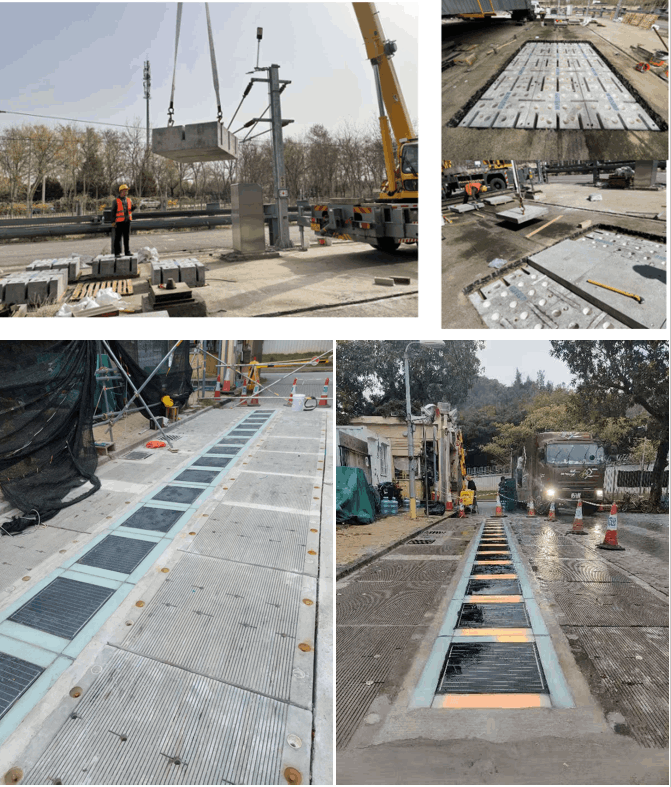

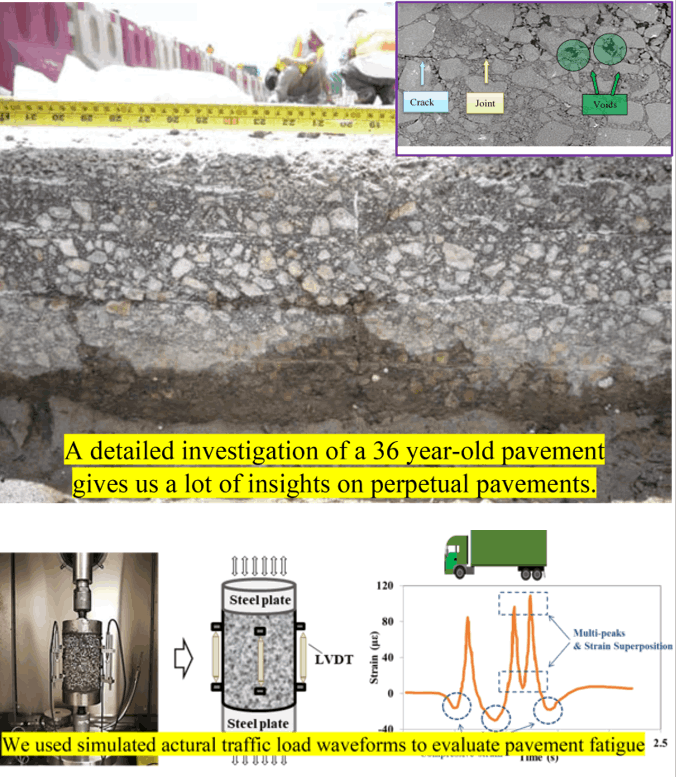

Perpetual Road

Perpetual road is made of pavement structure that can last at least 50 years. I was involved in incorporating the mechanistic-empirical pavement design principles into pavement design in Kentucky. In Hong Kong, I assisted in the development of flexible pavement design guide based on the mechanistic principles. In these studies, we found that the perpetual road is the most environmentally friendly solution, because material, energy, and green-house gas emission can be greatly reduced. However, perpetual road pavement structure is difficult to be built. Through existing road pavements and theoretical research, we try to identify the key factors that affect the performance of perpetual pavement. We are in the process of developing new design criteria for perpetual roads and develop new materials for perpetual pavements.