Prof. John Xin (right) and Dr Fei Bin

Researchers at PolyU have developed a novel tungsten-based material to replace the lead used in protective garments, providing effective shield against high energy radiation such as X-rays.

Lead is commonly used to shield humans from harmful high energy rays. Most of us have had lead covers placed on us at the dental clinic or in other medical settings when X-rays are taken. But did you know lead is a toxic chemical that poses grave risks in its mining, processing, handling and disposal? The US Department of Health and Human Resources and the European Environmental Protection Agency have both called for its use to be curtailed, and not surprisingly given that it can cause behavioural problems, learning disabilities, seizures and even death in the worst possible cases. More stringent regulations on the sale and use of lead products are looming.

But what can replace lead shielding in clinical settings? Prof. John Xin and Dr Fei Bin at the Institute of Textiles and Clothing, have led a team to explore the use of tungsten, a non-toxic, non-reactive element that can be blended with plastics to produce a green material that has better shielding properties than lead.

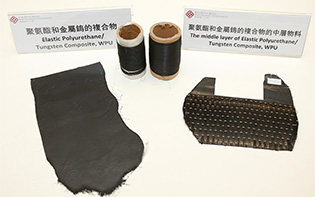

Polyurethane and tungsten are combined to form polyurethane/tungsten (WPU) composite and subsequently textile sheets that can be further processed into protective medical garments, and even curtains for use in airport security channels and nuclear power stations. The garments, in particular, are lighter, softer, more flexible, and more effective in radiation shielding than conventional leadimpregnated rubber garments.

WPU garments are expected to outlast their lead counterparts by a year and can be easily patched and fixed by heat presses. Even if the WPU garments require general disposal after repeated patching, the tungsten can be extracted and the garments can be sent to landfills without any concern for contamination. In contrast, damaged lead-impregnated garments cannot be repaired and the lead cannot be extracted for recycling.

The researchers expressed hope that the new garments would replace their conventional counterparts, and bring great benefits to users of X-ray and operators of high energy producing facilities. The research team has applied for two patents in the Chinese mainland, and the WPU composite won a Silver Medal at the 2016 International Invention Innovation Competition in Canada. ♦