3D printing

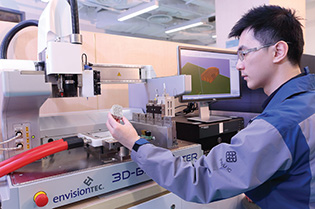

With 3D printing playing an increasingly important role in innovation and technological advances across a range of fields, PolyU has opened its University Research Facility in 3D Printing (U3DP) to support teaching, learning and research. Unique in the local higher education sector, the facility is Hong Kong’s largest in terms of the range and quantity of equipment available.

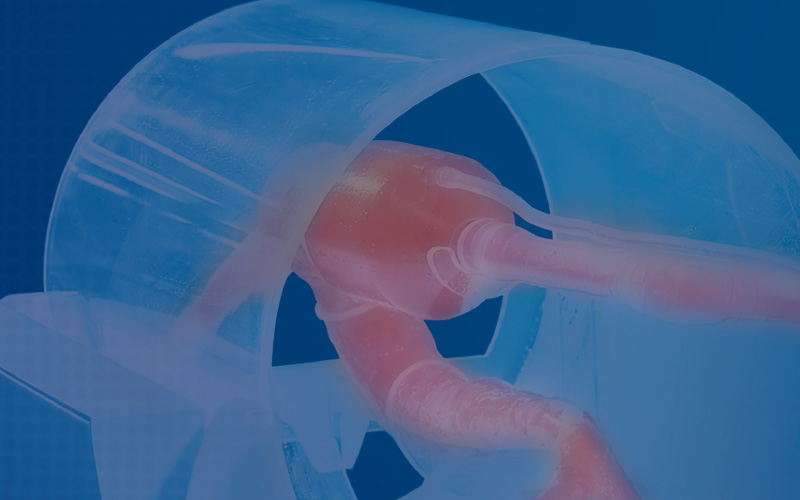

3D printing, a small-scale manufacturing process that uses digital models to produce physical items in layer by layer extrusion, has recently experienced such growth in use and technological advances that it is heralding in a new era of industrialisation. As large, complex machinery is no longer needed for rapid prototyping and product fabrication, companies and even individuals can create products in new ways.

From left: Queen Elizabeth Hospital Consultant (Medical) Dr Michael Lee Kang-yin, PolyU President Prof. Timothy W. Tong, Chairman of the Hospital Authority Prof. John Leong Chi-yan, PolyU Council Chairman Mr Chan Tze-ching, and Queen Elizabeth Hospital Associate Consultant (Medical) Dr Jason Chan Leung-kwai

Understanding the full importance of this transformation, PolyU has been developing technologies and models to advance the use of 3D printing, a process that culminated recently in the opening of the U3DP. The 620 square-metre facility offers a full range of advanced technologies from 3D scanning and computer aided-design modelling to printing, covering materials including metal, plastic, biocompatible resin, silver ink and graphene. Also incorporated in the facility is a 35-seat computer room and a 24-hour accessible Innovation and Incubation Hub featuring computers, Wi-Fi, projectors, and so on.

Addressing the Opening Ceremony on 19 April, PolyU Council Chairman Mr Chan Tze-ching said, “The U3DP will provide an innovative and inspirational environment for faculty members and students to make the best use of their capability in innovation and creativity”.

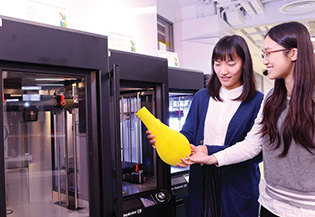

With the U3DP now open, students will be exposed to and learn about 3D printing and its related technologies early in their studies, which will benefit them as they seek to realise ideas and concepts in physical models during projects, especially final year and postgraduate projects. The facility will also be used in co-curricular activities such as competitions, helping to foster in students the innovative approaches to problem solving needed for a new generation of entrepreneurs.

The establishment of central research facilities is part of the University’s Strategic Plan. The U3DP is the fourth centre that PolyU has established, which will provide an inspirational environment for academic staff and students to realise their innovative ideas and excel in their research.

PolyU academics will be able to use the facility to prototype and develop new structures, materials, devices and sensors etc. With the expertise in 3D printing they already have bolstered by the equipment available, they will also be able to provide technical advice and consulting services to industry.

The U3DP will serve as one of PolyU’s prime platforms for fostering innovation and business incubation. It will further PolyU’s already robust University-industry collaboration, particularly in the realm of knowledge transfer and the benefits it brings to the wider community.