energy storage for electric cars

The supercapacitor invented by Prof. Eric Cheng Ka-wai can be integrated into car body panels

such as roofs, doors and trunk lids.

PolyU has developed a supercapacitor and an energy-storage suspension system for a new generation of electric vehicles.

Energy storage has long been the most critical challenge for eco-friendly electric vehicles, which consequently remain unpopular in Hong Kong. Recent years have seen a new wave of supercapacitors complementing or even replacing batteries as energy storage devices to improve vehicles' performance. Now, a research team led by Prof. Eric Cheng Ka-wai of PolyU's Power Electronics Research Centre has gone a step further in developing both a supercapacitor that can speed up charging and an energy-storage system used with a vehicle's suspension system.

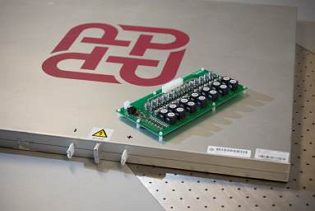

Using newly developed special packaging and built-in power electronics technologies, the Body Integrated Supercapacitor is only 4 cm thick both in flat or curved shapes. It can be integrated into car body panels such as roofs, doors and trunk lids, making best use of space in car body to maximise energy storage.

Compared with a battery pack, the supercapacitor generates more instant current and electrical power when the car is accelerating, and absorbs more current and power during quick stops or rapid deceleration. The overall system is thus highly efficient.

The spring-like actuator can use the recycled energy generated from suspension and vibration to charge the vehicle's battery.

An electromagnetically induced supercapacitor is much safer and more reliable than a battery reliant on chemical synthesis. When used in an electric car, it can be charged up within three to five minutes for 30 km of travel, and can withstand one million charge cycles. With the advantages of saving car space, maximising energy storage and compatibility with and applicability to various vehicles, the supercapacitor offers an attractive alternative energy source for electric vehicles.

The team has also developed a Linear Reciprocating Switched Reluctance Actuator that can be installed in modules in a car's suspension system and can even be placed on movable parts of any modes of transport, such as the seats and doors of trains and airplanes.

"When the vehicle travels over bumps, the suspension system oscillates and some of the resulting oscillation energy is absorbed by the system, whereas conventionally that oscillation energy is always dissipated," Prof. Cheng explains. The spring-like actuator not only improves safety and driving comfort, but also recycles the energy generated from suspension and vibration to charge the vehicle's battery. ♦